20E2125

| Period: | 2022-09-01 to 2026-08-31 |

|---|---|

| Funder: | Federal Ministry for Economic Affairs and Climate Action |

| Project Manager: | Lisa Zander |

| Divison: | Materials and Corrosion |

| Team: | High Temperature Alloys |

Refractory metal alloys are one of the most promising material classes to enable applications beyond 1100°C, while keeping high mechanical strength and corrosion resistance. In this temperature range only Ni-based superalloys are currently used for structural applications. However, their highest possible working temperature is limited to approx. 1100°C, simply due to the melting temperature of nickel. Refractory metals offer significantly higher melting temperatures, which would also enable higher working temperatures, leading to a potential increase in efficiency in, e.g., gas turbines. Requirements for the base refractory metal are, among others: low density (reduction in weight = increase in energy efficiency) and high availability (cost efficiency).

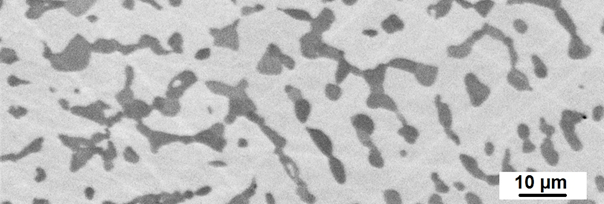

Chromium is a possible base refractory metal candidate, but in its pure form it is not corrosion-resistant enough due to its high susceptibility to nitridation and because it is also prone to the formation of volatile species at very high temperatures in air. In previous projects at the DFI, especially Cr-Si alloys were investigated. By alloying 5-13 at.% Si to pure Cr, a precipitation-hardened structure of an A2 matrix (Cr solid solution) and intermetallic A15 precipitates (Cr3Si) can be created. The A15 phase offers increased creep and oxidation resistance, while the A2 phase offers some ductility and fracture toughness. Molybdenum, as a further alloying element, can equally substitute for Cr in both phases and increases the melting point of the alloy. In the A15 phase, Mo further increases the creep resistance and leads to solid solution hardening and increased nitridation resistance of the A2 phase. A finer overall microstructure was also attributed to the addition of Mo to Cr-Si alloys.

The aim of this project is to develop a Cr-rich Cr-Mo-Si alloy for application temperatures above 1100°C. For this purpose, in a first step, a series of samples with Cr/Mo ratios between approx. 1.3 and 8.2 with a constant Si content are produced by arc melting. The resulting microstructures are studied as a function of the heat treatment and the Mo content, and the oxidation behavior at 1200°C in air is tested. The most promising alloy composition(s) will then be used for powder production in order to utilize powder metallurgy. With these powder metallurgy press and sinter processed samples, extensive mechanical high-temperature investigations will become possible, so that an application window for the developed alloy can be defined.

back

Das Projekt 20E2125 wird im Rahmen des fünften zivilen Luftfahrtforschungsprogramms (LuFo V) vom Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Lisa Zander

Tel.: +49 69 / 7564-531

E-mail: lisa.zander

L. Koliotassis, E.M.H. White, M.C. Galetz, Adv. Eng. Mater. 2301906 (2024)