From the particle to the cell:

> Powder synthesis of noble metal and oxide catalysts

> Physical-chemical characterisation

> Electrode coating

> Testing of electrode materials in PEM, DMFC, SOFC, and SOEC test benches

> Testing of powder materials in glas or stainless steel tube reactors up to 900 °C / 10 bar including gas analysis using gas chromatography

> Electrochemical charakterisation of flow battery components in laboratory cells and test benches

Wet-chemical syntheses from batch to continuous operation:

> Determining the kinetics of wet-chemical solid syntheses

> Use of a highly flexible, continuous apparatus with adapted dwell-time distribution

> Organic and aqueous synthesis of solids at up to 150 °C and 5 bar

> Optionally microwave-aided syntheses

> Production of specific powder materials up to 250 g per week

> Design, planning and construction of a custom-made apparatus at laboratory scale

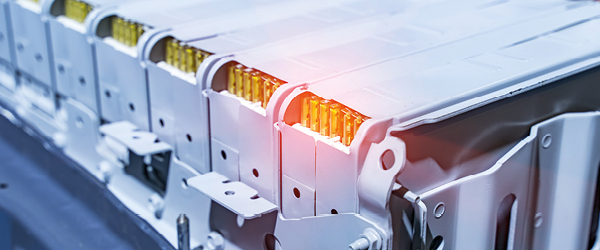

For our society we pursue the goal of a sustainable energy supply using renewable energy sources. This requires future-proof battery and fuel cell technologies for the storage and conversion of renewable energy forms.

In the area of solar and wind power, the redox flow technology is currently becoming increasingly significant. But also the operation of electrolysers contributes to the exploitation of new resources e.g. based on CO2 ("Power to Fuel"). Our research teams Applied Electrochemistry, Energy Storage and Conversion as well as Sustainable Electrochemistry have many years of expertise in the area of batteries and fuel cells. Our scientists have a wide range of methods at their disposal for working on industrial projects. We can accompany our partners from the catalyst development up to the characterisation of industral battery components. For this we can conduct, for example, catalys syntheses, electrode coatings, electrochemical tests in laboratory cells, and practical tests in battery test stations.

For the characterisation of flow battery components (electrodes, membranes, electrolytes) several laboratory test stations as well as a commercial test station are available. The ageing of materials is investigated in long-term tests. For online monitoring of the charge state we employ electrochemical and spectroscopic methods.

One of the test stations facilitates analyzing the activity and selectivity of powder materials in a glass or stainless steel tube reactor at up to 900 °C /10 bar. Additionally the gas is analyzed using gas chromatography. Battery/fuel cell components can be investigated under half cell and full cell conditions, and numerous electrochemical methods, such as cyclovoltammetry and impedance spectroscopy, are employed.

Custom-made stainless steel and oxide catalysts at the scale of few grammes up to 100 grammes can also be synthesized. For this we employ various wet-chemical routes such as sol-gel, impregnation/reduction and hydrothermal, and the produced catalysts are characterized comprehensively. Various coating techniques are used such as screen printing, ultrasonic spraying, doctor blade, and calendering.

The electrochemical conversion of precursors using gas diffusion electrodes (GDE) is becoming increasingly important. Some examples are hydrogen oxidation in fuel cells as well as oxygen reduction in fuel cells and in metal/air batteries. In large-scale processes, for example, the electrochemical usage of CO2 for the production of methanol or synthesis gas will play a significant role in the future. In the area of technical electrolysis the development of the oxygen consumption cathode presents a substantial innovation of the chlorine-alkaline electrolysis.

Dr.-Ing. Jean-François Drillet

Energy Storage and Conversion / Chemical Technology

Telephone +49 6172 89938-476

Dr. Claudia Weidlich

Applied Electrochemistry / Chemical Technology

Telephone +49 6172 89938-633