L. Koliotassis, E.M.H. White, M.C. Galetz

Advanced Engineering Materials 2301906 (2024), DOI: 10.1002/adem.202301906

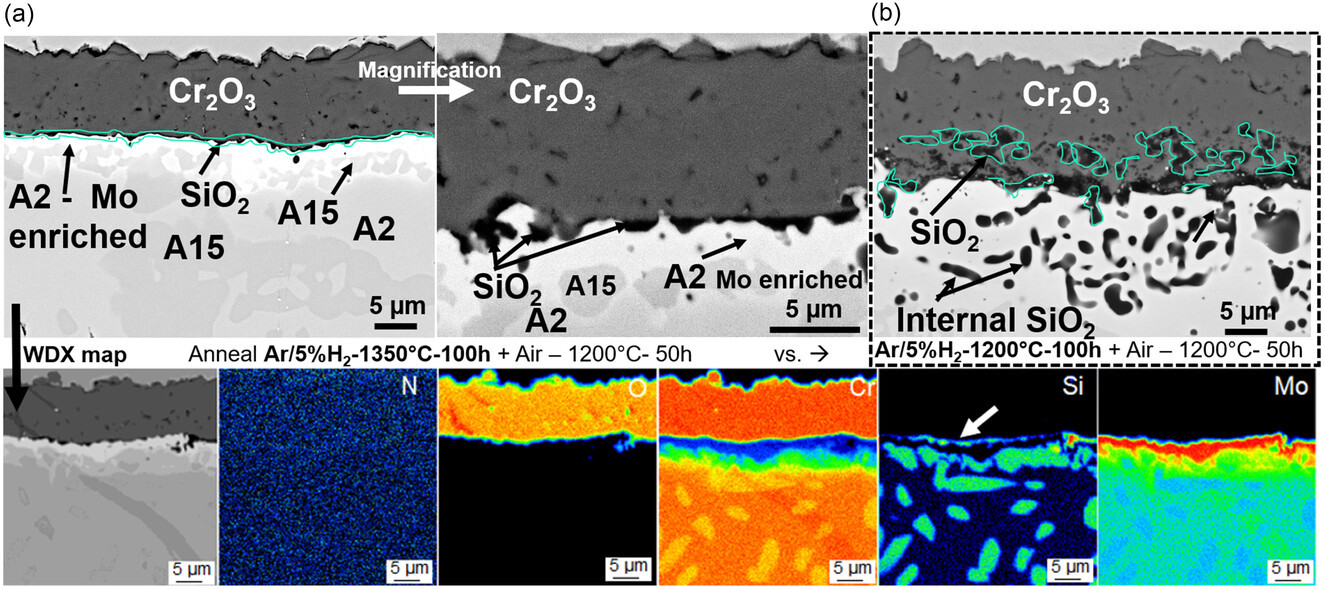

The influence of Mo (10–40 at%) additions to Cr–8 at%Si is systematically studied by analyzing arc-melted alloys in the as-cast and annealed state. The oxidation resistance is tested by thermogravimetric analysis (TGA) at 1200 °C in air for up to 100 h. Samples are characterized by X-ray diffraction, scanning electron microscopy, and wavelength-dispersive X-ray spectroscopy. The studied Cr–xMo–8Si alloy series shows a beneficial effect of Mo on the corrosion behavior. For all of the investigated Mo contents, no nitridation is observed and the oxide scale adhesion is improved. An increased amount of intermetallic A15 phase leads to the formation of a SiO2 scale beneath the Cr2O3 layer during high-temperature exposure. The internal SiO2 layer inhibits further internal oxidation of the A15 phase. Uniform size and distribution of A15, benefits the formation of a duplex oxide scale. Cr–25Mo–8 at%Si, shows the most promising oxidation behavior. The TGA data follows the paralinear law, with both the growth rate, kp, and volatilization rate, kv, of Cr2O3 being reduced by adding 10–25 at% Mo. A binary Cr/Mo–Si phase diagram is generated in order to determine accurate annealing conditions and estimate the stability range of the metastable σ phase.