JU201/12

| Period: | 01.01.2007 - 31.12.2008 |

|---|---|

| Funder: | Deutsche Forschungsgemeinschaft (DFG) |

| Project Manager: | Holger Bueb, Dr. Jean-François Drillet |

| Research Group: | Chemical Technology |

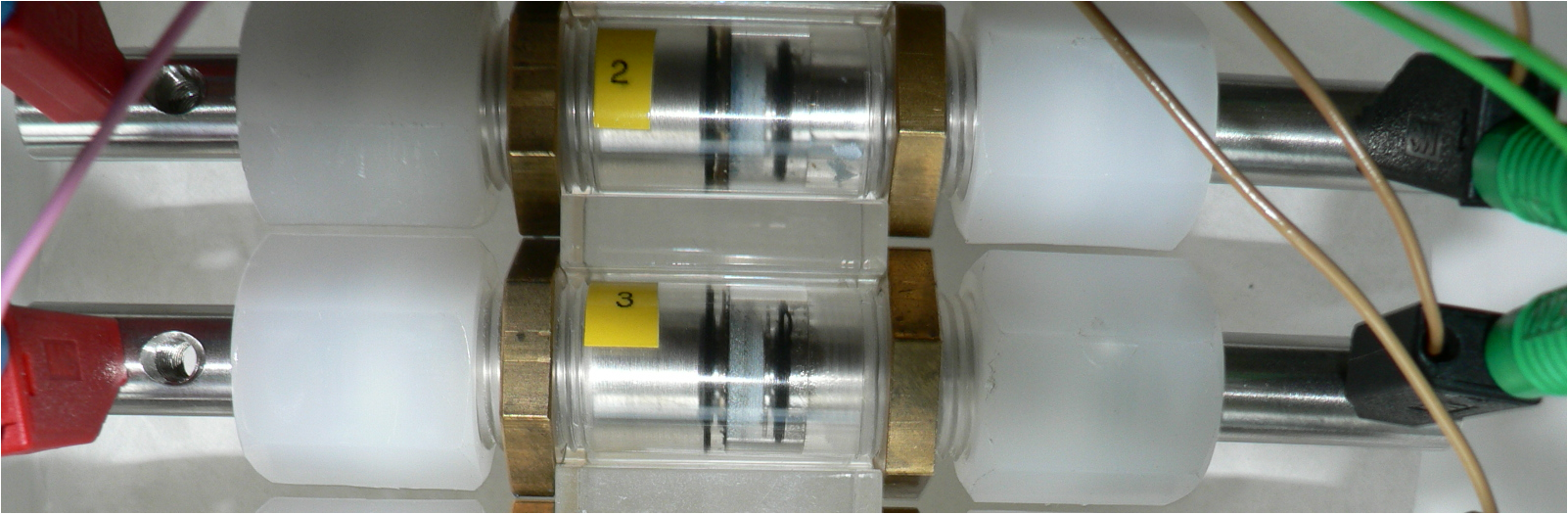

In the first part of this project was examined the influence of the chemical treatment of S ingle W alled C arbon N anotubes (SWCNTs) on their specific surface and/or their efficiency as catalyst support regarding the methanol oxidation in the half cell and in the D irect M ethanol F uel C ell (DMFC). The portion of C arbon N ano-T ubes (CNTs) in the raw material was increased by oxidation in air with 300°C of 38 to 50%. Ni and/or Y- Remainder catalyst could be solved by treatment in concentrated nitric acid best out. On the T ransmission E lectrons M icroscope (TEM) photographs nano-tube bundles, remainder catalyst as well as amorphous carbon were clearly recognizable. A good dispersion of the Pt-catalyst on the SWCNTs probe oxidized with air was probably obtained due to their high specific surface compared with Vulcan. The electro-chemical investigations by means of cyclic voltammetry in the half cell confirmed that via the chemical treatment of the SWCNTs with nitric acid a clear increase of the reloading stream and/or the electro chemical specific surface takes place. In the DMFC have the MEAs with air-oxidized or with nitric acid treated nano-tubes a clear increase of the cell achievement opposite the untreated carbon nano-tubes as well as the carbon Vulcan caused. With oxygen and an anodic as well as cathodic Pt catalyst loading of 1 mg cm-2 a maximum achievement could be achieved of approx. 157 mW cm-2 with a pressure of 2 bar (abs). These results show that treated SWCNTs can function as alternative material to the Vulcan. Further investigations are necessary nevertheless regarding methanol permeation within the MEA, in order to e.g. quantify the influence of the CNT structure on the methanol Crossover. With view on a reduction of the methanol crossovers not fluoridated high temperature polymer electrolyte membranes, which were developed of Institute for chemical process engineering in Stuttgart (Dr. J. Kerres), are tested. The moreover one a self-supporting group electrode from buckypaper than base material is developed. Carbon nano-tubes are dispersed in surfactant and filtered off by means of vacuum filtration. On the filter cakes developing thereby a second dispersion from surfactant and carbon nano-tubes on it solitary catalyst particles, is also filtered off. From these two filtration procedures such a double layer filter cake results, whereby the first layer serves the group electrode as carrier of the reaction layer (second layer). The double layer filter cake is improved by a drying procedure to the rising up group electrode. In addition the group electrode contains to the better connection of the electrode material Teflon and Nafion, in order to ensure the ionic conductivity of the reaction layer.

J.-F. Drillet, H. Bueb, R. Dittmeyer, U. Dettlaff-Weglikowska, S. Roth

Einfluss der Reinigung und Funktionalisierung von Kohlenstoff-Nanoröhren auf deren katalytische Eigenschaften in der Direct Methanol Fuel Cell-Anode

Chem.-Ing.-Tech. 80 , No.11, (2008), 1711-1718

Dr.-Ing. Jean-François Drillet

Tel.: 069 / 7564 - 476

E-Mail: drillet

J.-F. Drillet ... S. Roth, Journal of Power Sources, 195 (2010), 8084-8088

J.-F. Drillet ... S. Roth, J. Electrochem. Soc., 156/10 (2009), F137-F144

J.-F. Drillet ... S. Roth, Chem.-Ing.-Tech., 80 (2008), 1711-1718