| Period: | 01.07.2001 - 30.06.2004 |

|---|---|

| Partner: | - |

| Funder: | Deutsche Forschungsgemeinschaft |

| Project Manager: | Prof. Dr. K. Jüttner |

| Research Group: | Electrochemistry |

Aims

The preparation and characterisation of a catalyst system for application at the anodic section in a PEM fuel cell (hydrogen and methanol oxidation).

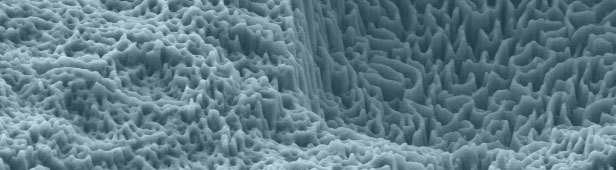

In conventional PEM fuel cells the membrane electrode assembly (MEA) consists of a system of proton conducting ionomer membrane and platinum-based catalyst supported by conducting carbon. The efficiency of the catalyst depends on the contact zone between catalyst/carrier carbon/membrane, where electron and ion transfer as well as approach and removal of reactants and products take place. Conducting polymers, e.g. polypyrrole, used as catalyst carrier material could be an interesting variant to the conventional concept. By modifying polypyrrole with platinum a three dimensional matrix coated with catalytic active platinum nano-particles is formed, which has a high surface and an improved 3-phase contact. By synergetic interaction between catalyst and conducting polymer the CO-tolerance and catalyst contamination by reaction byproducts of the methanol oxidation could be improved.

Working plan

I. Optimising the preparation methods of catalyst system.

II. Characterisation of catalyst activity and determination of correlation between structure and efficiency

III. Nanoscale polypyrrole and platinum catalyst; preparation and characterisation of this new catalyst system

IV. Development of a membrane electrode assembly on Nafion-membrane + polymer + catalyst

V. Testing of membrane electrode assembly in a laboratory fuel cell.

Results

The catalyst system was prepared by different methods: nanoparticles of polypyrrole/platinum are fixed in carbon-fleece; polypyrrole/platinum are deposited on a Nafion-membrane. With these catalyst systems methanole oxidation was studied.

back