GA 1704/12-2

| Laufzeit: | 01.10.2019 - 30.06.2023 |

|---|---|

| Partner: | Lehrstuhl Metallische Werkstoffe, Universität Bayreuth |

| Geldgeber: | Deutsche Forschungsgemeinschaft (DFG) |

| Bearbeiter: | Beyza Öztürk |

| Abteilung: | Materialien und Korrosion |

| Team: | Hochtemperaturkorrosion |

Titanium and its alloys extensively find place in aerospace, automotive, chemical and biomedical industries due to the combination of their outstanding mechanical properties with low density and good corrosion resistance. However, the successful implementation of commercially available Ti6Al4V in the intended applications is limited due to its poor tribological properties (wear and friction). Therefore, “Oxygen Diffusion Hardening (ODH)” has been developed to enhance the wear properties and coating adhesion of Ti6Al4V. In this heat treatment process, the chemical bonding of the oxide to the metallic base material is improved by the formation of an oxygen diffusion zone in the subsurface region.

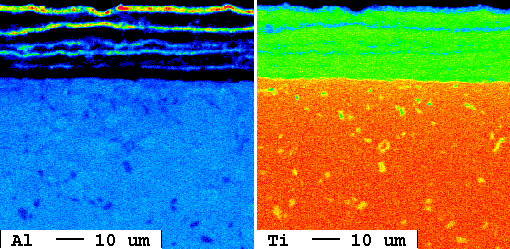

The purpose of this project is to investigate the oxygen diffusion hardening in three systems and hence to improve the mechanical properties of the oxide layers. The three systems are commercial 1) Ti6Al4V, 2) Ti6Al4V coated with Zr and the high-entropy alloy 3) TiZrNbHfTa (each 20 at. %). Ti6Al4V is the most commonly used titanium alloy. Besides the application of ODH to Ti6Al4V alloy, an additional promising approach is to coat the Ti6Al4V with zirconium using pack cementation. The potential advantage of the zirconium coating is to avoid the formation of thermally grown titanium oxide, which has a complex structure compared to zirconium dioxide. The third system, the high entropy alloy TiZrNbHfTa, contains all three elements (Ti, Zr, and Hf) with prominent oxygen solubility. The particular interest of the project is to investigate the near-surface layers formed during oxidation. Suitable heat treatment parameters are developed for all three systems in order to improve both coating adhesion and wear resistance. The latter is primarily evaluated in a high-temperature pin on disc tribometer test.

zurück

Gefördert durch die Deutsche Forschungsgemeinschaft (DFG) - GA 1704/12-2

Beyza Öztürk

Tel.: 06172 89938-362

E-Mail: beyza.oeztuerk

Abschlussbericht (pdf, 1,1 MB)

B. Öztürk, M. Rudolphi, E. M. H. White, D. Dickes, U. Glatzel, M.C. Galetz, High Temperature Corrosion of mater. 101 (2024), 1341

D. Dickes, Y. Zhao et al., Appl. Phys. Lett. 124 (2024), 071903

B. Öztürk, E.M.H. White, D. Dickes, U. Glatzel, L. Mengis, M.C. Galetz, Surface and Coatings Technology 487 (2024)

B. Öztürk, L. Mengis, D. Dickes, U. Glatzel, M.C. Galetz, Oxidation of Metals 97 (2022)

D. Dickes, B. Öztürk, R. Völkl, M.C. Galetz, U. Glatzel, Materials and Corrosion 24 (2022)