B. Öztürk, M. Rudolphi, E.M.H. White, D. Dickes, U. Glatzel, M.C. Galetz

High Temperature Corrosion of mater. 101 (2024), 1341-1351, DOI: 10.1007/s11085-024-10288-1

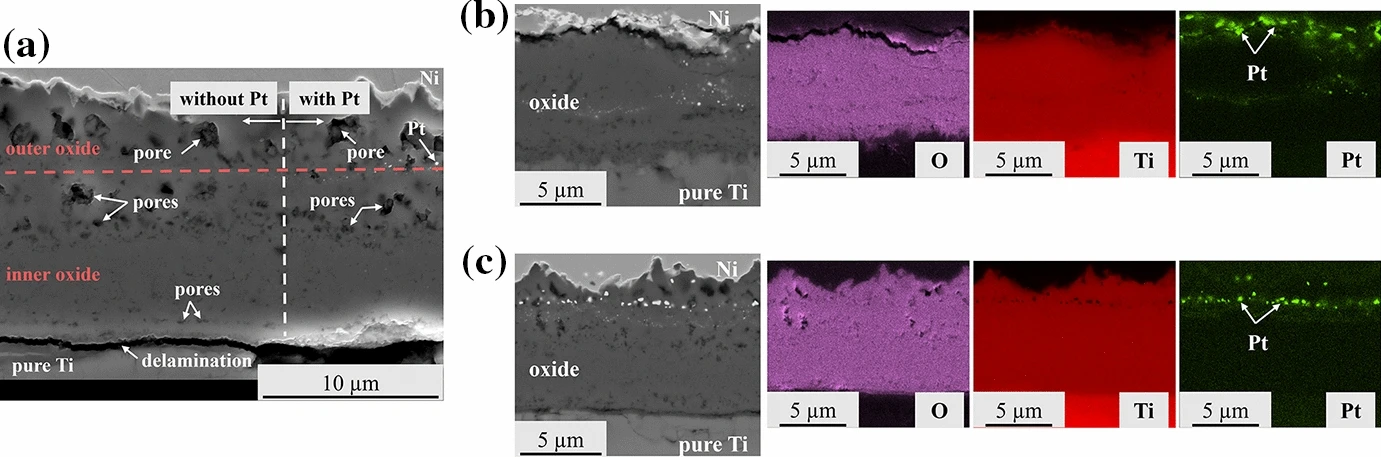

Titanium and titanium alloys are extensively used in the aerospace, automotive, and medical industries due to their high chemical and mechanical stability. In a previous study, the influence of water vapor on the growth of the oxide scale and the formation of the oxygen diffusion zone (ODZ) for Ti-6Al-4V was investigated using a 6-zone furnace. To elucidate the effect of water vapor on the oxide scale growth and ODZ, without the effect of alloying elements on diffusion, a systematic comparative study at 500, 600, and 700 °C for up to 500 h was carried out on pure Ti. Inert marker experiments showed that outward scale growth and diffusion of Ti4+ were promoted by water vapor. Additionally, the extent of oxygen enrichment in the subsurface zone (ODZ) as a function of temperature and time was determined for pure Ti by nanoindentation profiles and compared with results obtained for Ti-6Al-4V. The thickness of the ODZ increased with increasing temperature and time for dry air and humid air. The diffusion of oxygen ions within pure Ti and Ti-6Al-4V was not significantly affected by the presence of water vapor in the oxidizing environment. The effect of water vapor on the oxide scale spallation was found to be less critical for pure Ti when compared to Ti-6Al-4V.