D. Dickes, Y. Zhao, F. Baier, B. Öztürk, R. Völkl;, T. Li, M.C. Galetz, U. Glatzel

Appl. Phys. Lett. 124 (2024), 071903, DOI: 10.1063/5.0190771

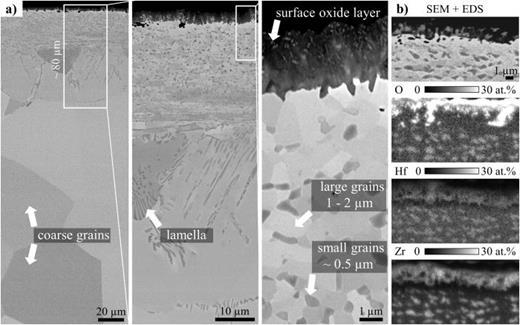

(a) Detailed backscattered SEM images of TiZrNbHfTa after the two-step oxidation process with (b) corresponding EDS elemental mappings.

Reprinted from Appl. Phys. Lett. with permission from AIP Publishing according to the Creative Commons license.

Aiming for an increased surface hardness and a better wear resistance of TiZrNbHfTa, we investigate a two-step process combining oxidation of rolled, ultrafine-grained, single-phase bcc TiZrNbHfTa in air at 550 °C with a vacuum heat treatment process at 1200 °C, including subsequent quenching. The first process step is associated with the formation of a surface oxide layer, a phase decomposition of the bulk, and oxygen ingress into the bulk, leading to an oxygen-enriched subsurface region containing internal oxides. The second process step is capable of restoring the single-phase nature of the bulk TiZrNbHfTa. At the same time, the presence of a compact surface oxide layer of 1–2 μm and an oxygen-enriched subsurface region underneath is preserved. The oxygen present in the subsurface region stabilizes a two-phase regime consisting of a Hf- and Zr-rich hcp phase and an Nb- and Ta-rich bcc phase, with the oxygen being interstitially dissolved predominantly in the hcp phase.