Light dependent processes often suffer from poor light penetration depths. Resonant inductive coupling of LEDs (Wireless Light Emitters, WLE) allows an efficient and homogeneous internal illumination of various conventional reactor types.

• Photocatalytic synthesis in organic chemistry

• Waste water treatment

• Ambient and exhaust air cleaning

• Cultivation of phototrophic microorganisms (e.g. algae)

Electromagnetic induction is often used for a wireless energy transfer. The coupling of two coils becomes stronger when the secondary side of the loosely coupled coil resonates. (Resonant inductive coupling, RIC)

RIC is for example used in “QI wireless power transfer“ (e.g. charging of smartphones).

RIC enables the use of freely moving light sources inside a reactor which leads in a homogeneous illumination. A comparison of an externally and a WLE illuminated reactor can be found here.

The Developement of the WLE is done in cooperation with the Institute of Measurement and Sensor Technology (IMS).

Light driven surface ractions of heterogeneous nanoparticles are realized through exitation of an electron into a higher energy level. If the energy is high enough the electron at the conduction band can be used to reduce a certain substance. On the other hand an electron can be inserted into the space left by the excited electron of the valence band (hole) which enables oxidations too.

An overview of recent heterogeneous photoredox reactions can be found here.

[1] G. Ciamician, (1908), Sur Les Actions Chimique De La Lumiere. Bull. Soc. Chim. Fr. [4] 3, i.

Coating Concept

The coating allows homogeneous illumination and excitation of the whole catalyst layer and prevents light penetration into the reaction medium. Due to this improvement light sensitive and strongly light absorbing reactants can be used without a damage or loss of light. The coated WLE spheres can be used like common catalyst pellets which are easily separable from the reaction medium.

Coating procedure

The UV-transparent polymer shell is activated in an oxygen plasma to enable the attachment of SiO2. The SiO2 layer is prepared through a radio frequency sputtering process to obtain a homogeneous UV-transparent thin film which promotes the adhesion of the photocatalyst and protects the polymer against the solvent and photocorrosion. To enhance the binding of the TiO2 nanoparticles a thin TiO2 layer is deposited through reactive Ti sputtering and a dip-coating process is applied to finally immobilize the catalyst.

Photocatalysts

Besides TiO2 many other semiconductor materials are known to act as heterogeneous photocatalysts. Especially nanoparticle oxdies (e.g. BiVO4, ZnO, Fe2O3) are commonly utilized, also sulfides (e.g. CdS, SnS) as well as organic polymers (g-C3N4, carbon nanodots) are often used. Frequently co-catalysts (e.g. Ag, Au, Pt, Co, Fe) are added to enhance the photocatalytic performance. Another interesting approach to ehnance the range of specific catalysts is the use of homogeneous photocatalysts immobilized onto a heterogeneous photocatalyst support (dye-sensitizing).

The choice of the right catalyst material is determined by the specific demands of each reaction. Each material has different properties like band gap, band position, charge carrier mobility etc. which have to be considered. Generally, each photocatalyst can be coated as a nanoparticle with the above described method, however the different properties of each material require other conditions. Of course also other coating techniques can be applied to get a coating which fulfills the specific requirements.

Innovative Coatings and Materials at DFI

The DECHEMA Research Institute has build up great experiences over a long period for many different special coating solutions. The actual materials and coatings research is focused in the research cluster Functional Surfaces.

Catalyst Materials and Coatings are mainly developed in the Chemical Technology group to produce novel electrodes and photocatalysts.

Slow Motion Video of the 17 L Demo Reactor filled with coloured WLE:

100 mL Lab-scale reactor filled with UV-WLE (365 nm) and umbelliferrone as a fluorescent dye:

One topic of the Chemical Technology group is up-scaling of photoreactions. Commonly used flow techniques (photo membrane-, micro- and falling film- reactors) are appropriate for continuous processes. However, the up scale of photocatalytic batch systems is challenging due to small light penetration depths. WLE are investigated for photocatalytic reactions in batch and continuous systems and compared with other reactor types. The advantage of the WLE sytem is the simple scaleability by just raising their number. Further, they overcome the light penetration depth issue via homogeneous internal illumination of the whole reactor.

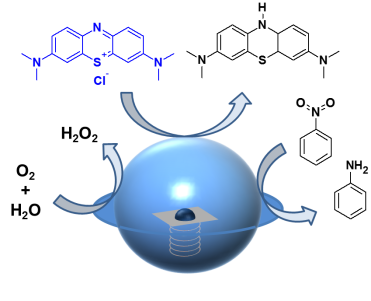

The TiO2 coated WLE can be used for various types of reactions. Three different reactions have been carried out to prove the universal applicability of the concept. As an example from the field of organic synthesis the reduction of nitrobenzene to aniline has been shown. Also the simultaneous oxidation of water and reduction of oxygen to yielding hydrogen peroxide could be shown. Further, as an example from the field of waste water treatment and a standard test for photocatalytic activity the decolouration of methylene blue was performed. Further information on those reactions can be found here.

We could already demonstrate the functionality of the WLE system up to a scale of 17 L. We successfully performed photochemical reactions up to a scale of 2 L, where we could show identical process data (conversion, yield) with smaller scales if the specific energy input was kept constant via the density of employed light emitters. This therefore allows a seamless scale-up of the system by directly transferring the reaction protocols without the need of adaptation at larger scales.

By optimizing the energy transfer, we can now achieve radiant power densities up to about 100 W/L even in large reactors, this corresponds to about one mole per liter per hour of photon flux and thereby allows productivities in the range of kg per liter and day.

The efficiency of the wireless energy transfer is in the range of 85%, the overall energy efficiency from wall plug to light energy inside the reactor is up to 34% which is comparable to other high efficiency irradiation systems. However, in our case, there are no losses through off-target illumination and reflection from the reactor walls. We also achieve a very homogenous distribution inside the reaction which helps to reduce losses through insufficient kinetics in bright spots.

The WLE can readily be industrially manufactured at low cost and in large quantities and are available in different emission wavelengths (UVA, blue, green, red, white). For the polymer shells, we have different materials available. However, due to their excellent chemical and thermal stability we typically employ fluorinated polymers such as ETFE.

Are you interested in working toghether with us? Please contact us directly and see our Services.

Do you look for special experimental set-ups or prototypes? Our Mechanical Workshop is working closely together with our researchers to create specified solutions for your needs.

B. O. Burek, H. T. Duong, K. Hochradel, A. Sutor, M. Rupp, E. K. Heilmann, K. Lovis, J. Z. Bloh, Eur. J. Org. Chem. (2021), e202101180

Intensification of Photobiocatalytic Decarboxylation of Fatty Acids for the Production of Biodiesel

H. T. Duong, Y. Wu, A. Sutor, B. O. Burek, F. Hollmann, J. Z. Bloh, ChemSusChem, 14 (2021), 1053-1056

B. O. Burek, A. Sutor, D. W. Bahnemann, J. Z. Bloh, Catal. Sci. Technol., 7 (2017), 4977-498.

Photobioreactors with internal illumination – A survey and comparison

M. Heining, R. Buchholz, Biotechnol. J., 10 (2015), 1131-1137.

Internal illumination of photobioreactors via wireless light emitters: a proof of concept

M. Heining, A. Sutor, S. C. Stute, C. P. Lindenberger, R. Buchholz, J. Appl. Phycol., 27 (2015), 59-66.

Method for Optimizing the Field Coils of Internally Illuminated Photobioreactors

A. Sutor, M. Heining, C. P. Lindenberger, R. Buchholz, IEEE TRANSACTIONS ON MAGNETICS, 50 (2014), 2-5.

Dr. Jonathan Bloh

Tel.: +49 6172 89938-387

E-mail: jonathan.bloh

B. O. Burek, A. Sutor, D. W. Bahnemann, J. Z. Bloh, Catal. Sci. Technol., 7 (2017), 4977-4983