T. König, S.P. Hagen, S. Virtanen, M.C. Galetz

Metall Mater Trans A (2022), DOI: 10.1007/s11661-022-06807-x

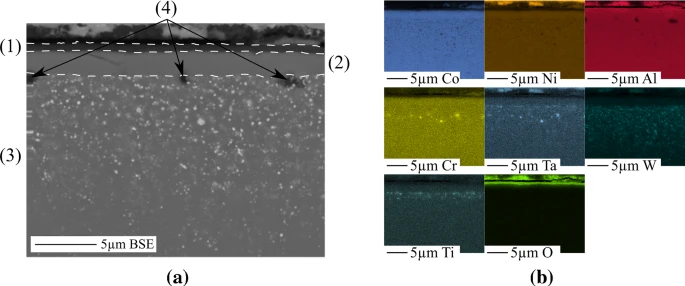

Co-based superalloys have been developed as candidate materials to replace Ni-based superalloys in hot sections of turbine engines, however, their oxidation resistance is limited. Therefore, in this work chromium and aluminum diffusion coatings were developed via the pack cementation process for novel γ/γ′-strengthened superalloys of the Co–Ni–Al–W system. This alloy system also offers the opportunity to vary the cobalt-to-nickel ratio and the tungsten content systematically to investigate their influence on the coating process. The coating process was shown to successfully enrich the surfaces of such alloys either in aluminum or chromium. For Al, the result was the formation of (Co, Ni)Al on top of an interdiffusion zone, while for chromium a Cr-rich layer in solid solution with the substrate along with the formation of σ-phase were observed. The coating formation mechanisms are discussed for both coatings in the light of activities and phase formation.