C. Grimme, K. Ma, R. Kupec, C. Oskay, E.M.H. White, A.J. Knowles, M.C. Galetz

Surface and Coatings Technology 485 (2024), 130891, DOI: 10.1016/j.surfcoat.2024.130891

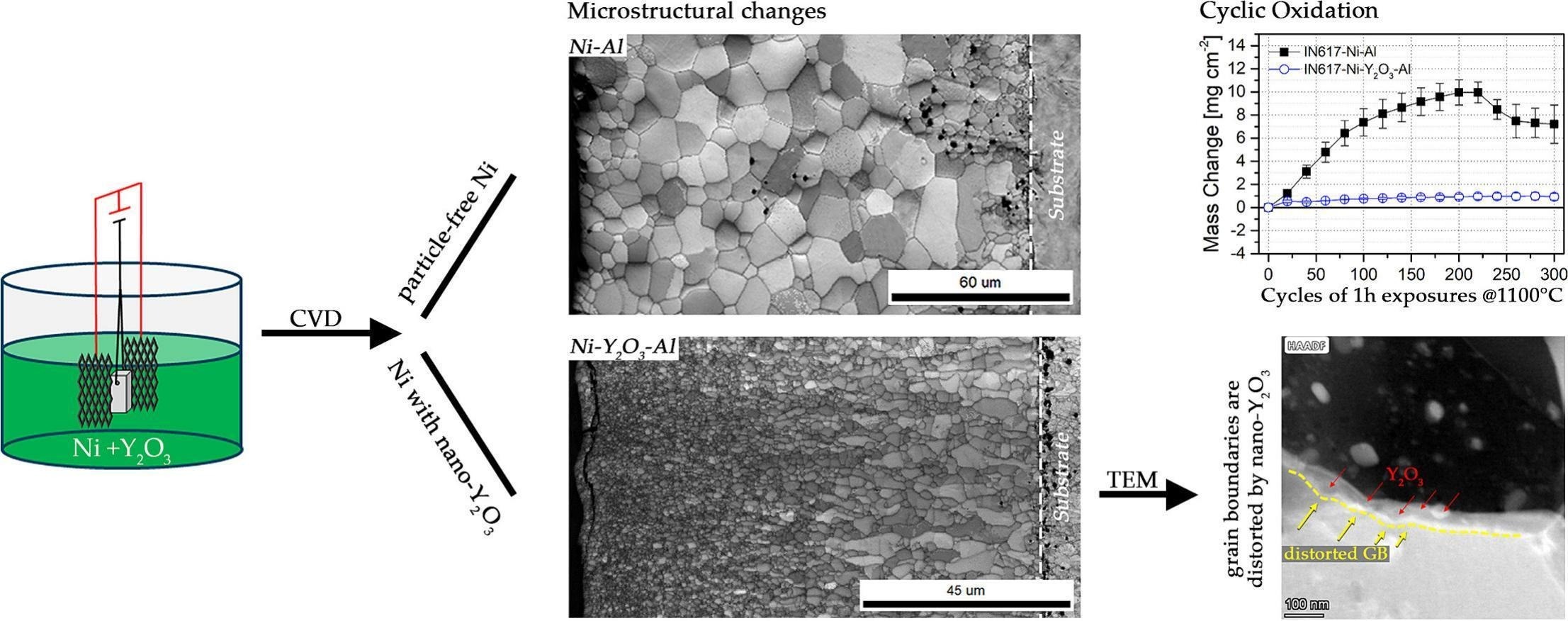

Incorporating reactive elements (RE) into turbine coatings is a well-established surface treatment. However, suboptimal RE concentrations can lead to compromised strength, heightened brittleness, and reduced adhesion. In contrast, RE oxides offer advantages of avoiding these detrimental effects, counteracting corrosion phenomena induced by V2O5 compounds and enhancing oxidation resistance. A notable challenge lies in optimizing RE oxide particle incorporation and understanding the influence of particles in coating microstructures. This study focuses on developing Ni-Al and Ni-Cr-Al type metal matrix composite (MMC) coatings on Inconel 617 (IN617), containing up to 11 vol% of Yttria (Y2O3) nanoparticles. Y2O3 nanoparticles and Ni were co-electrodeposited on IN617 followed by either pack aluminizing or a two-step chromizing and aluminizing process. An even distribution of Y2O3 nanoparticles was observed throughout the entire 100 μm coating thickness, leading to significant grain refinement in the sub-micron to nano range in both coating types. Y2O3-strengthened coatings were subjected to oxidation at 1100 °C and hot corrosion at 700 °C and were compared to their Y2O3-free counterparts. Present at grain boundaries, Y2O3 markedly enhanced the oxidation and corrosion resistance by reducing interdiffusion, improving the oxide scale adherence and binding V2O5, highlighting the potential of this method for advanced turbine blade coatings.