D. Dickes, B. Öztürk, F. Baier, P. Berger, E.P. George, R. Völkl, M.C. Galetz, U. Glatzel

Corrosion Science 217 (2023), 111159, DOI: 10.1016/j.corsci.2023.111159

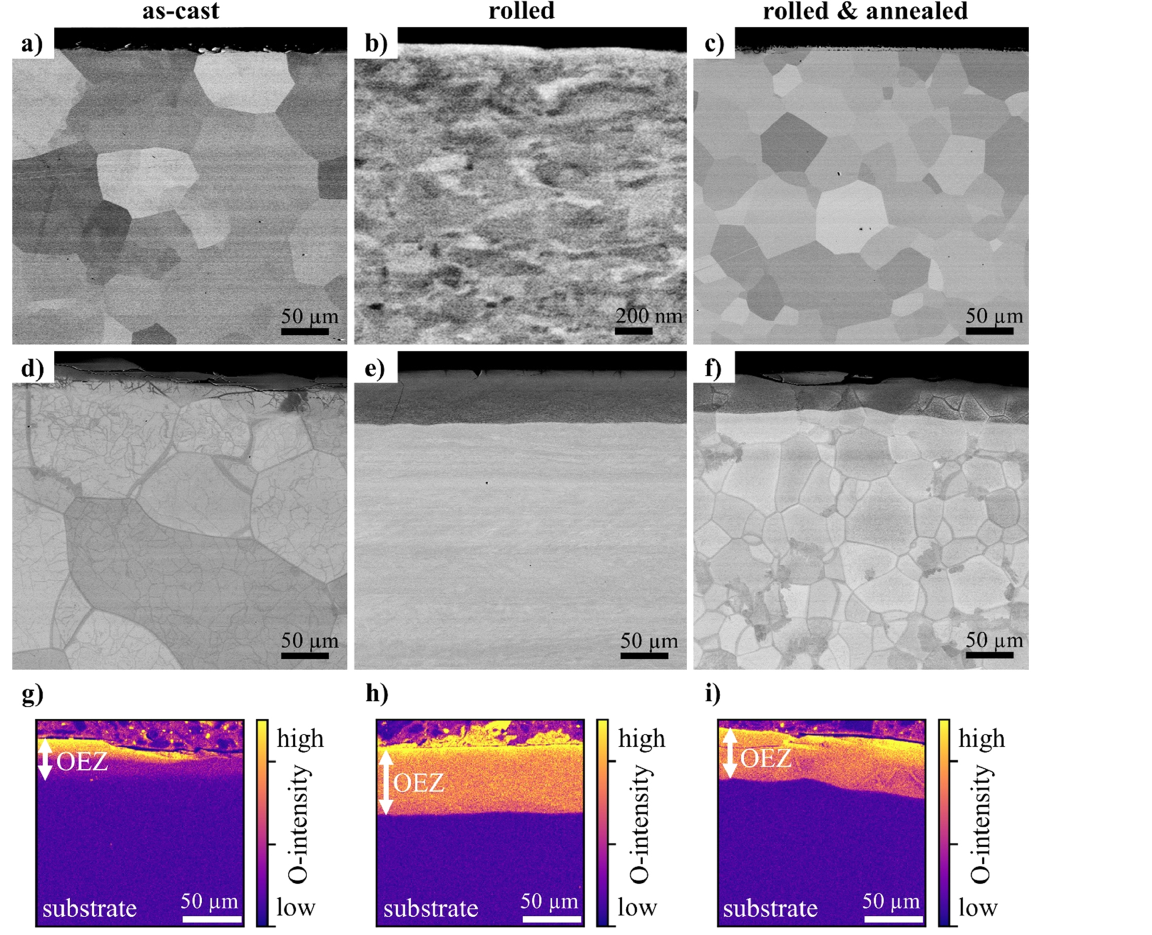

We investigate the oxidation of TiZrNbHfTa high entropy alloy between 550 °C and 650 °C as a surface hardening method. Coarse-grained specimens with grain boundaries perpendicular to the surface exhibit catastrophic oxidation, while ultrafine-grained, cold-rolled specimens show a continuous mass gain and the formation of an adherent, µm-sized, vitreous oxide layer. Underneath, TiZrNbHfTa decomposes into a bcc- and an hcp-phase, while selective internal oxidation of hafnium and zirconium occurs upon oxygen inward diffusion. Oxygen concentration- and microhardness-depth profiles confirm an increase in oxygen concentration and hardness at the surface, raising the initial hardness by four times to 1522 ± 64 HV0.5.