22355 N

| Period: | 2022-06-01 to 2025-08- 31 |

|---|---|

| Partner: | German Aerospace Center (DLR) |

| Funder: | IGF |

| Project Manager: | Julian Zander, Katharina Beck |

| Division: | Materials and Corrosion |

| Team: | High Temperature Corrosion |

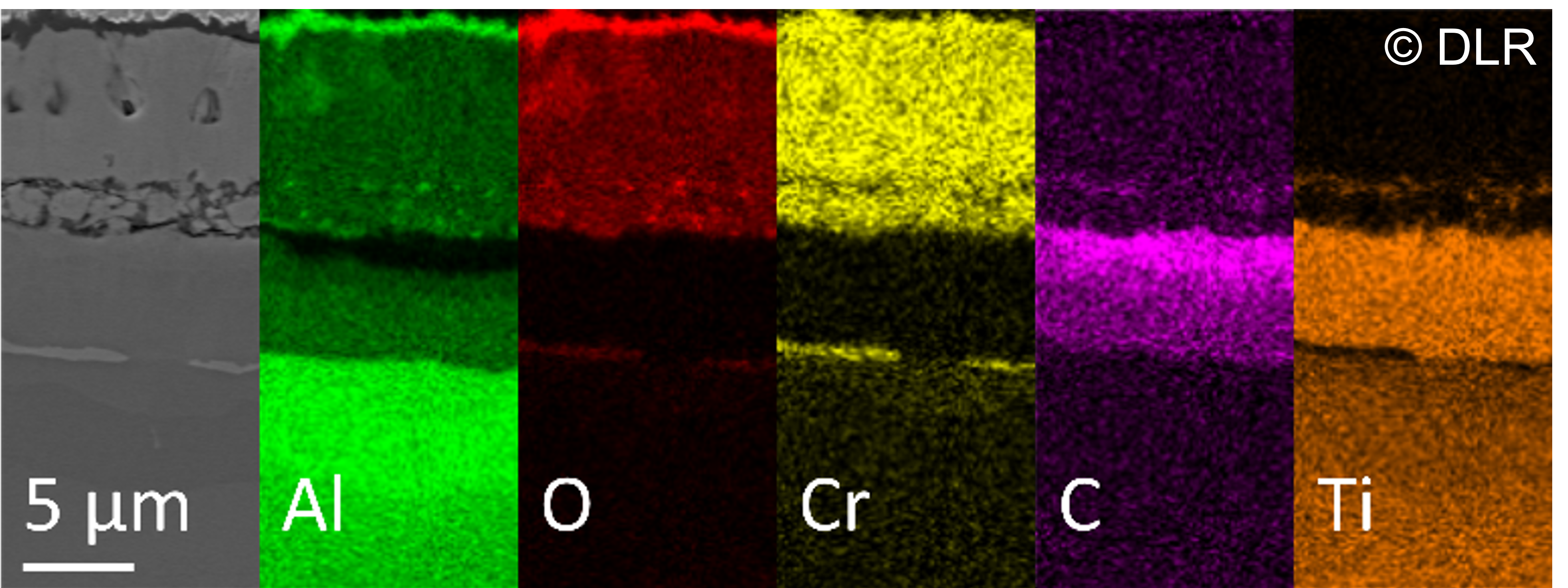

In 2011, the European Union issued a policy (Flightpath 2050) setting new targets for the aviation industry, including a 75% reduction in CO2 emissions. The optimization of the aircraft turbines used is essential to achieve these targets. A fundamental approach to increasing the efficiency of aircraft turbines is to reduce weight by using lightweight materials. In this context, titanium aluminides have already been used to replace conventional Ni alloys in the low-pressure areas of turbines. However, the application possibilities of the titanium aluminides are rather limited due to their low oxidation resistance above 700°C and their susceptibility to various wear mechanisms. The application range of titanium aluminides could be significantly extended by the deposition of protective MAX-phase coatings. These coatings combine metallic and ceramic properties and exhibit a high melting point, oxidation resistance as well as wear resistance. This would enable the use of the light titanium aluminides in further stages of the aircraft turbine and lead to significant weight savings. In addition, the coatings developed in this project will also be applied to the novel SiC/SiC CMCs. This will break completely new ground in the development of coatings for this class of materials.

back

Das IGF-Vorhaben wird durch das Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Julian Zander

Tel.: +49 69 / 7564-658

E-mail: julian.zander

Katharina Beck

Tel.: +49 69 / 7564-196

E-mail: katharina.beck