01IF22689N BG/2

| Period: | 2023-01-01 to 2025-06-30 |

|---|---|

| Partner: | RWTH Aachen – Steel Institute (IEHK) |

| Funder: | IGF |

| Project Manager: | Beyza Öztürk |

|

Department: |

Materials and Corrosion |

| Team: | High Temperature Alloys |

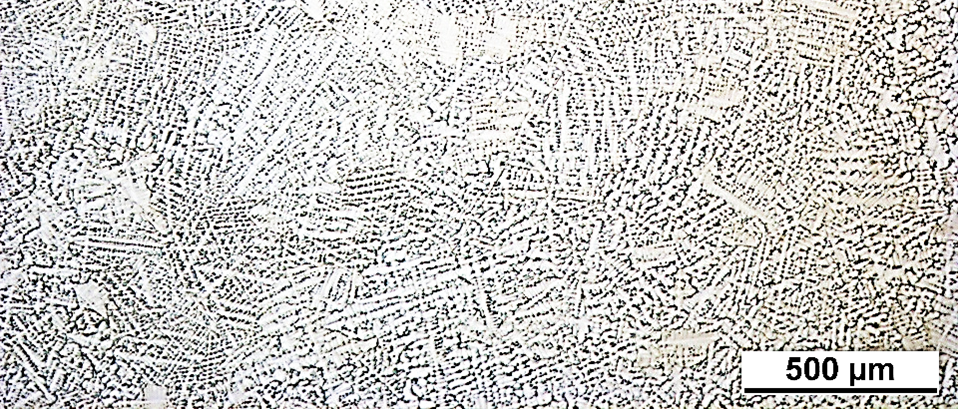

In a previous AiF-funded project ("AM Hochtemperaturbauteile", Grant number 20904 N), it was shown that Ni-Cu alloys with Cu content could exhibit metal dusting attack despite the inhibiting effect of Cu. In this project, Ni-Cu alloy is chosen as the base material, and oxide formers were added to the Ni-Cu alloy to form a barrier and improve its resistance to metal dusting. Aluminum oxide is suitable for this purpose as Al2O3 is slow-growing and thermodynamically stable under Metal Dusting conditions. In this project, the process parameters for powder atomization of Ni-Cu alloys with high aluminum content will be determined. Then, process parameters for low-defect Laser-Powder-Bed-Fusion-Fusion-Process (LPBF) will be established. In the meantime cast and later the additively produced components will be investigated as a function of aluminum content. Finally, an overview will become available of process-structure-property relationships in terms of mechanical properties and corrosion resistance of the alloys.

back

Das IGF-Vorhaben wird durch das Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Beyza Öztürk

Tel.: +49 69 / 7564-362

E-mail: beyza.oeztuerk