IGF 20136 N

| Period: | 01.07.2019 - 31.12.2021 |

|---|---|

| Partner: | Christof Langer; fem

Prof. Dr. Detlef Bahnemann, Technical Chemistry, University Hannover (TCI) |

| Funder: | AiF |

| Project Manager: | Dr. Sigrid Benfer |

| Team: | Electrolytic Corrosion |

Air pollution by nitrous oxides is currently one of the main problems for urban air quality. The Federal Environment Agency (UBA) concludes in its 2016 report that more than half of all traffic-related measuring stations exceed the annual average annual limit of nitrogen dioxide (NO₂). For this reason, the corrosion group of the DECHEMA-Forschungsinstitut (DFI) in cooperation with the Forschungsinstitut Edelmetalle+Metallchemie (fem) and the Leibniz Universität Hannover (TCI) initiated a research project for the development of photocatalytic anodizing surfaces.

The aim of this research project is to provide anodically oxidized aluminum substrates with photocatalytic properties, on the one hand to reduce nitrogen oxide pollution in cities and on the other hand to provide the surfaces with self-cleaning and antibacterial properties. The incorporation of the titanium dioxide nanoparticles into the highly structured anodized layer causes harmful nitrogen oxides on the anodized surface to be converted by photocatalysis into non-toxic nitrates with the help of sunlight. The resulting nitrates are washed from the surface by water (e.g., rain or spray). In addition to harmful nitrogen oxides, organic contaminants can be decomposed by photocatalysis. This property is supported by the effect of "superhydrophilicity", which is generated by the hydroxyl functionality of titanium dioxide.

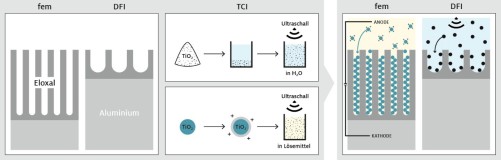

The project involves three steps, namely the targeted structuring of anodized surfaces, the synthesis of photocatalytically active titanium dioxide particles and their incorporation into the anodic pores. The production of the smallest possible, photoactive TiO2 nanoparticles (ideal: particle sizes ≤20 nm) with simultaneous variation of the surface charge (zeta potential) in different solvents is a challenging task. The technical challenge in developing the layers is to apply them in such a way that the high photocatalytic activity is not impaired and a firm bond between the substrate and the photocatalytically active titanium oxide is ensured. Within the project two independent process variants will be used to incorporate photocatalytically active TiO2 nanoparticles into the pore structure of the anodized aluminum. These are electrophoretic deposition and impregnation via dip coating (s. Fig.).

Figure: Scheme of the electrochemical and ultrasonically assisted dip impregnation of previously synthesized TiO2 nanoparticles into the different meso or macroporous surfaces.

The advantages and disadvantages of the individual processes will also be investigated in order to determine the application-oriented use of the respective process variant. It is assumed that by electrophoretic incorporation more particles can be introduced into the pore structure, than in the dipping process. Among other things, the degree of filling of the anodizing pores is important because some surfaces (e.g., aluminum facades) undergo an abrasive cleaning process at regular intervals. After such cleaning processes the photocatalytic activity results only from the stored photocatalytic material. In this case the electrophoretically impregnated surfaces might by advantageous. On the other hand, the more cost-effective, possibly ultrasound-assisted dipping method is better suited for surfaces in the field of hygiene, sanitary and medical technology, which are rarely exposed to an abrasive cleaning process. In order to minimize the financial burden on SMEs when implementing the project results, both process variants can be integrated into the existing anodization lines.

back

Das IGF-Vorhaben Nr. IGF 20136 N der Forschungsvereinigungen Verein für das Forschungsinstitut für Edelmetalle und Metallchemie e.V. (fem), DECHEMA e.V. und GfKORR - Gesellschaft für Korrosionsschutz e.V. wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Dr. Sigrid Benfer

Tel.: 069 / 75 64-382

E-Mail: benfer

S. Benfer, J.Z. Bloh, S. Funk, C. Langer, S. Läufer, S. Lederer, A. Pashkova, E.B. Sa, W. Fürbeth

Jahrbuch Oberflächentechnik Band 78, S. 259-273

Stephan Lederer, Sigrid Benfer, Jonathan Bloh, Rezan Javed, Aneta Pashkova, and Wolfram Fuerbeth

Corros. Mater. Degrad. 2023, 4(1), 18-30