L. Korell, K. Beck, A.R. Chitra, F. Hinrichs, C. Oskay, E. White, M. Heilmaier, M.C. Galetz

Materials and Corrosion (2025), DOI: 10.1002/maco.70048

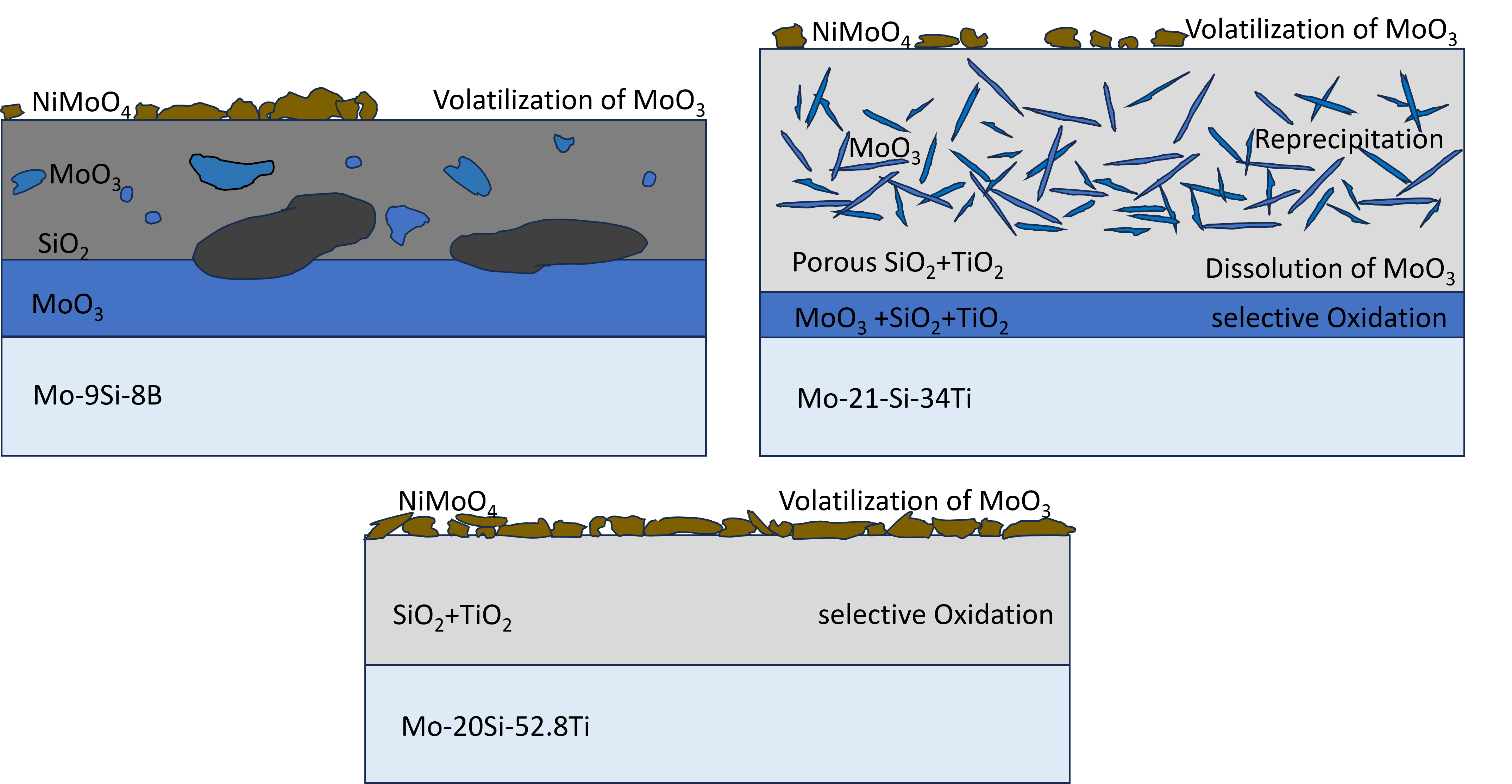

To enhance turbine efficiencies by increasing gas inlet temperatures, new materials must be developed which can withstand harsh corrosive environments and provide sufficient mechanical properties at elevated temperatures. The hot corrosion behavior of the promising alloy candidates Mo-20Si-52.8Ti (at.%), Mo-21Si-34Ti (at.%) and Mo-9Si-8B (at.%) under mixed 60mol.% Na2SO4 and 40mol.% NiSO4 deposit in dry synthetic air plus 0.1vol.% SO2 were investigated at 700°C. Optical and electron microscopy, EPMA and XRD were employed for analysis. Comparing the results to tests with pure Na2SO4 reveals that the Mo content significantly impacts the corrosion attack if Ni is present. Na2MoO4 is observed during corrosion besides the initial eutectic phase between Na2SO4 and NiSO4. With melting points below 700°C, both compounds are capable of dissolving the surrounding material. However, the formation of NiMoO4 is energetically favored, transforming the initial liquid eutectic sulfate mixtures. Therefore the corrosion rate is lowered by the addition of NiSO4 to the Na2SO4 deposit.