033RC022E

| Laufzeit: | 1.3.2020 - 31.3.2024 |

|---|---|

| Partner: | DLR, Sunfire, TU Dresden |

| Geldgeber: | Bundesministerium für Bildung und Forschung (BMBF) |

| Bearbeiter: | Dr. Isabela Dainezi |

| Abteilung: | Materialien und Korrosion |

| Team: | Innovative Keramiken |

High-temperature co-electrolysis is a technology that enables the conversion of water vapour and carbon dioxide into synthesis gas by using renewable electricity. Synthesis gas is a mixture of hydrogen and carbon monoxide, which can be converted by various downstream syntheses into so called e-fuels, such as e-diesel or e-kerosene, or into e-chemicals such as methanol. With this technology, the greenhouse gas emissions from sectors that are difficult to electrify, such as the chemical industry as well as air, ship and heavy goods traffic, can be reduced.

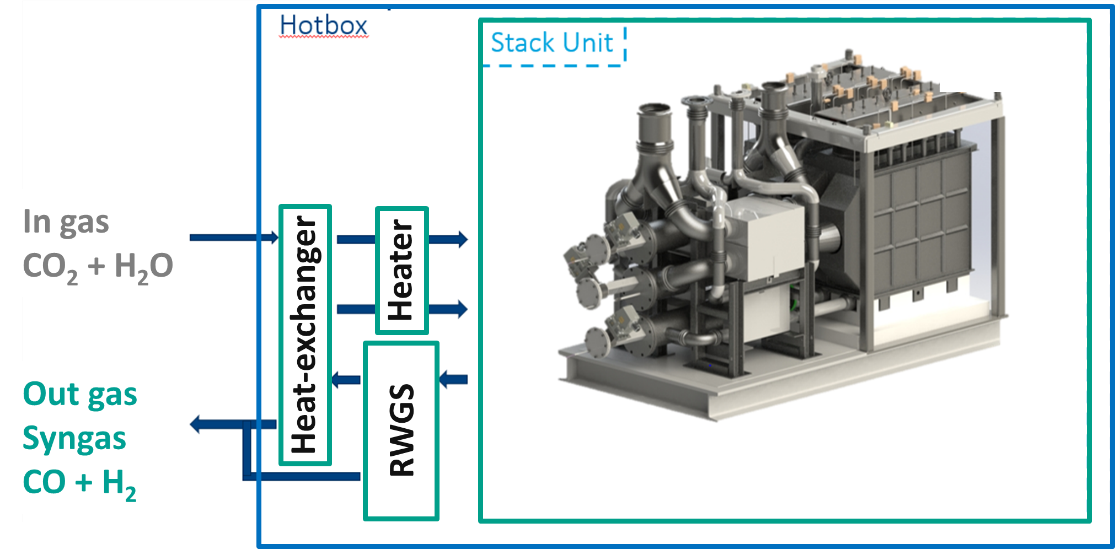

The core technology of high-temperature co-electrolysis is oxygen-ion-conducting solid oxide cells. These have been continuously developed in recent years in order to be able to provide high-temperature co-electrolysers for the Megawatt scale in the future. The aim of the present project is to develop and optimize the peripherical equipment of the Balance-of-Plant (BoP) components, such as heat exchangers, heaters, chemical reactors and sensor elements, in order to become more competitive in terms of costs, durability and operational reliability. In particular, the high operating temperatures of up to 900°C and the corrosive gas atmospheres pose a challenge here. The aim of the project is therefore the development and upscaling of crucial BoP components and their testing in an optimized high-temperature co-electrolyser module.

During this project, DFI is evaluating the materials selection for a heater an RGWS reactor and a heat exchanger. These components are important in the BoP for setting the temperature and composition of the input and output gases of the process. The resistance of the materials to high temperatures and aggressive media environments will be evaluated.

zurückDr. Isabela Dainezi

Tel.: 069 / 75 64-134

E-Mail: isabela.dainezi