126 EN

| Laufzeit: | 01.10.2014 - 28.02.2017 |

|---|---|

| Partner: | Fraunhofer-Institut für Umwelt-, Sicherheits- und Energietechnik UMSICHT (Deutschland) und MateriaNOVA (Belgien) |

| Geldgeber: | Bundesministerium für Wirtschaft und Energie (BMWi) über AiF |

| Bearbeiter: | Dr. Ali Solimani |

| Arbeitsgruppe: | Hochtemperaturwerkstoffe |

Corrosion, erosion, sticking, and caking are widespread problems in power plants, caused by aggressive flue ashes with corrosive components such as sulfur, chlorine, and alkali-based low-melting salts. Furthermore, the use/co-firing of a diversity of biomass or alternative fuels with lower quality enhance the problems arising from adhesion (caking, sticking) and the corrosion and erosion issues. As a result, the efficiency of the power plant decreases (lower heat transfer) and periodically service maintenance shutdowns have to be planned in order to clean the facilities and to change damaged parts, generating costs from 100,000 to €1 Million/day.

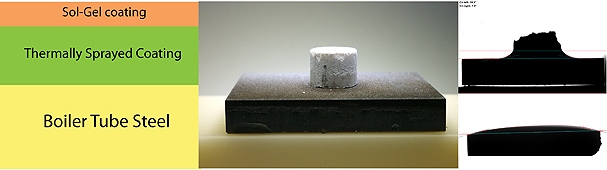

The innovative concept proposed in this research project combines thermally sprayed coatings functionalized with a sol-gel layer providing low wettability/sticking. FeCrAl alloy-based thermally sprayed coatings including targeted hard materials, such as Cr-carbides, will provide a suitable corrosion and erosion protection. The thin sol-gel layer, in combination with the thermally sprayed coatings, will reduce the sticking ability of aggressive liquid phases or solid flue ash particles.

The project is a collaboration between DECHEMA-Forschungsinstitut (Germany), Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT (Germany), and MateriaNOVA (Belgium).

zurück

Das IGF-Vorhaben Nr. 126 EN der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.