SCHU 729/24-2

| Laufzeit: | 01.09.2014 - 31.08.2016 |

|---|---|

| Geldgeber: | Deutsche Forschungsgemeinschaft (DFG) |

| Bearbeiter: | Dr. Hans-Eberhard Zschau |

| Arbeitsgruppe: | Hochtemperaturwerkstoffe |

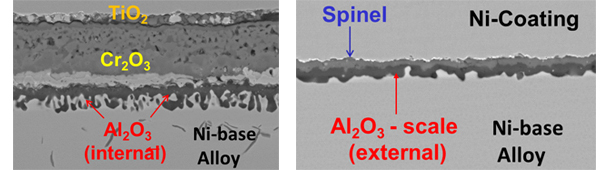

Ni-base superalloys with a relatively low amount of Al (2-5 wt.%) are often used in high-temperature technology, e. g. turbine blades in stationary gas turbines and aircraft engines. Due to their low Al-amount these alloys are unable to form a protective alumina scale by themselves. Therefore Al-rich coatings are applied to obtain a protective alumina scale. By using the halogen effect a dense protective alumina scale can be achieved even from the alloy itself. Fluorine is used as it achieves the best results. The adherent alumina scale shows good oxidation protection under isothermal conditions and over long oxidation times. However during cyclic oxidation the protective alumina scale partly spalls, probably due to a mismatch in CTE of the alloy and the top scale. The Reactive Element (RE) effect reduces the oxide growth rate, changes the structure of the top scale, and increases the adhesion of the oxide scale. Whereas in the present project phase the influence of the halogen effect has been studied, the proposed renewal phase will focus on the mechanism by combining both the halogen effect and RE effect. The investigations will include short and long oxidation times. Starting with isothermal oxidations to understand the behaviour of the halogen and the reactive elements, the emphasis will be on oxidation under cyclic oxidation conditions. A Ni-based model alloy and 1st and 2nd generation Ni-based superalloys are chosen for the studies. Three methods of RE-addition are compared: The reactive elements Y and Hf are doped on the surface via ion implantation and via magnetron sputtering, whereas a volume addition is performed by melting. As result an optimized data base for the combined halogen and RE effects will be obtained, which can be used to improve the adherence of the formed protective alumina scale.

zurückPD Dr. Mathias Galetz

Tel.: 069 / 7564-397

E-Mail: mathias.galetz

H.-E. Zschau, ..., M. Schütze, Nuclear Instruments and Methods in Physics Research B 365, Part A (2015), 202

H.-E. Zschau, ..., M. Schütze, Oxidation of Metals 83 (2015), 335

H.-E. Zschau, M. Schütze, F. King, Materials and Corrosion 65 (2014), 116

Abschlussbericht (pdf, 1,7 MB, auf Englisch)