| Laufzeit: | 01.06.2015 – 31.05.2019 |

|---|---|

| Partner: | Acciona Infrastructure, Accurec Recycling GmbH, Albufera Energy Storage S.L., CEA - Commissariat à l’énergie atomique et aux énergies alternatives, CEG - Elettronic Industriale S.p.a., Leitat Technological Center, NTNU - Norwegian University of Science and Technology, Solvionic, Torrecid S.A., Technische Universität Berlin, University of Southampton, Varta Microbattery GmbH |

| Geldgeber: |

European commission – research and innovation program Horizon 2020 Förderkennzeichen: 646286 |

| Bearbeiter: | Willi Peters |

| Arbeitsgruppe: | Technische Chemie |

Motivation

Lithium-Ion batteries have conquered numerous market segments due to their excellent energy storage and cycling properties. Nonetheless Li-ion technology is facing limitations in case of overcharge, deep discharge, overheating and short-circuits that may lead to decomposition of both electrodes and electrolyte and to consecutive cell ignition (thermal runaway). Within the last decade search for post Li-ion batteries has been intensified. Especially the trivalent aluminium cation is an interesting candidate that possesses a remarkable theoretical capacity density of 8040 Ah L-1 (vs. 2046 Ah L-1 for Li-ion). Moreover, aluminum is abundant and cheap. However anode passivation of aluminum (Al2O3) in aqueous electrolytes is a major concern for reversibility. Therefore, the use of non-aqueous electrolytes with good solubility and ion conductivity for for Al3+ should be the better strategy.

State of the Art

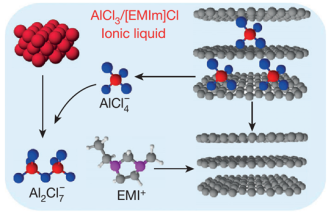

The best results for an Al cell so far have been published by Lin et al. who used an aluminum foil as anode, EMIMCl-AlCl3 as electrolyte and pyrolytic graphite as cathode (see figure 1). They presented a mechanically bendable battery that exhibited an excellent power density of 3000 W kg-1, while lasting 7500 cycles without decay 1.

Fig. 1 - An Al-ion cell, comprising an aluminium foil anode (left), EMIMCl/AlCl3 as electrolyte and a graphite cathode (right).1

Objectives

The ALION consortium aims at the introduction of Al-ion technology into the European market by using a holistic approach. Starting with the synthesis of intercalation materials, preparation and testing of electrode materials a variety of Ionic Liquids will be screened. The determination of electrochemical data will be used for simulation and optimization of the battery at a single cell level. Al-ion cells will be manufactured and tested according to technical standards by VARTA Microbattery. The whole process will be accompanied by environmental impact evaluations as well as battery recycling considerations. DFI activities focus principally on the development and screening of intercalation materials for the anode and the cathode of Al ion batteries

For more information about project partners and objectives, please go to: http://www.alionproject.eu/project/

Acknowledgements

The European Commission is gratefully acknowledged for financial support within the research and innovation program Horizon 2020. (Grant No.: 646286 – ALION)

Literature

1 M. C. Lin et al., Nature 520 (2015) 324

zurückDr.-Ing. Jean-François Drillet

Tel.: 06172 89938-476

E-Mail: jean-francois.drillet

G.A. Elia, K. Marquardt, K. Hoeppner, S. Fantini, R. Lin, E. Knipping, W. Peters, J.-F. Drillet, S. Passerini, R. Hahn Advanced Materials (2016) Progress Report

L. Ager-Wick Ellingsen, A. Holland, J.-F. Drillet, W. Peters, M. Eckert , C. Concepcion, O. Ruiz, J.-F. Colin, E. Knipping, Q. Pan, R. G. A. Wills and G. Majeau-Bettez Materials 11/6 (2018) 936

M. Eckert, W. Peters, J.-F. Drillet Materials, 11/12 (2018)

W. Peters, H. T. Duong, S.Lee and J.-F. Drillet PCCP 23 (2021) 21923