C. Schlereth, M. Weiser, E. White, P. Felfer, M.C. Galetz

Journal of Materials Science (2024), DOI: 10.1007/s10853-023-09260-2

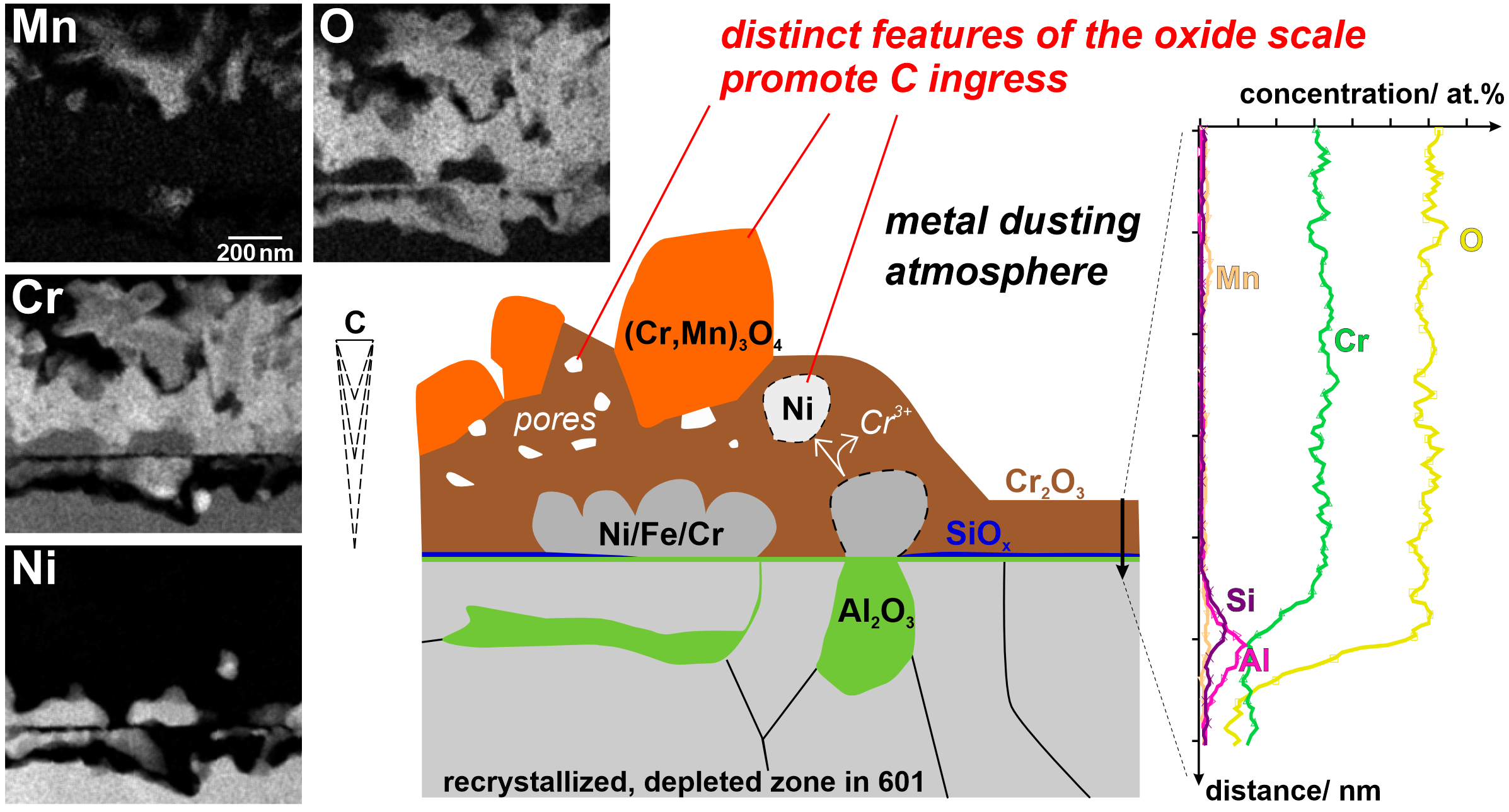

Chemical plants which process highly carbonaceous gases at elevated temperatures are prone to catastrophic corrosion by metal dusting. Typically, commercial alloys with high amounts of protective oxide scale formers (Cr, Al, and Si) are used in these environments. However, scale failure is still frequently observed after an incubation time initiating pits. In this study, the microstructure and subsequent metal dusting-induced failure of the oxide scale on the commercial Ni-based alloy 601 was analyzed. Samples were exposed in different aggressive metal dusting gases and characterized using metallographic cross sections, electron beam microanalysis (EPMA), scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), Raman spectroscopy and transmission electron microscopy (TEM). A thin and protective chromia scale formed in some regions with a continuous silica layer below. Across most of the alloy 601 surfaces, internal oxidation of Al could be linked to metallic particles in the outer scale. Additionally, MnCr2O4 was observed in the outer scale. Together with pores in the chromia, the spinel and metallic particles in the outer scale combined to provide pathways for carbon ingress. After exposure in a gas with a higher driving force for carbon deposition, a higher amount of carbon was incorporated in the growing oxide scale, resulting in earlier scale failure and metal dusting pit initiation.