J.P. Zander, S. Lederer, W. Fürbeth

Proceedings of the 15th World Conference on Titanium Chapter 3: Biomedical & Healthcare Applications (2024), DOI: 10.7490/f1000research.1119883.1

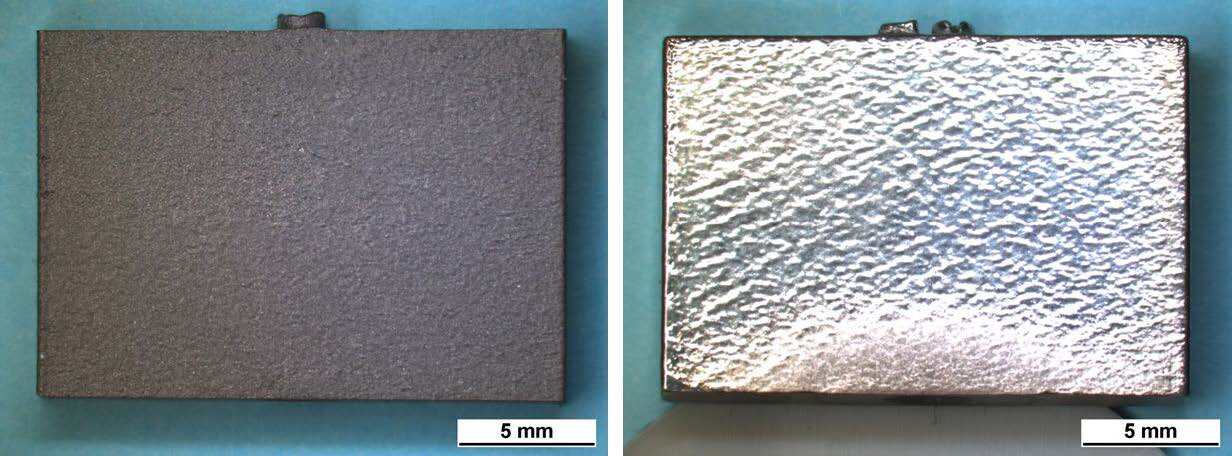

Additive manufacturing allows the fast production of small and complex parts with minimum waste for biomedical applications made of titanium alloys. However, the cytotoxicity of certain elements being widely used in these alloys has become a concern, initiating the development of new alloys avoiding their use as alloying elements. In this publication, surface engineering techniques like blasting and plasma electrolytic polishing have been applied to a new Ti2Mo alloy obtained by Selective Laser Melting (SLM) in order to enhance its surface properties. First aim of such surface engineering processes is to develop standardized surfaces for additively manufactured parts, comparable to conventionally produced parts. Residual stresses that arise due to the additive manufacturing process are examined as well as their potential impact on the mechanical and corrosion properties of the alloys. Via suitable heat treatment residual stresses can be lowered and adjusted. Additionally, the corrosion properties are determined using potentiodynamic polarization and tribocorrosion testing.