E.M.H. White, L.M. Rueschhoff, S.W. Martin, I.E. Anderson

Batteries 10 (2024), 386, DOI: 10.3390/batteries10110386

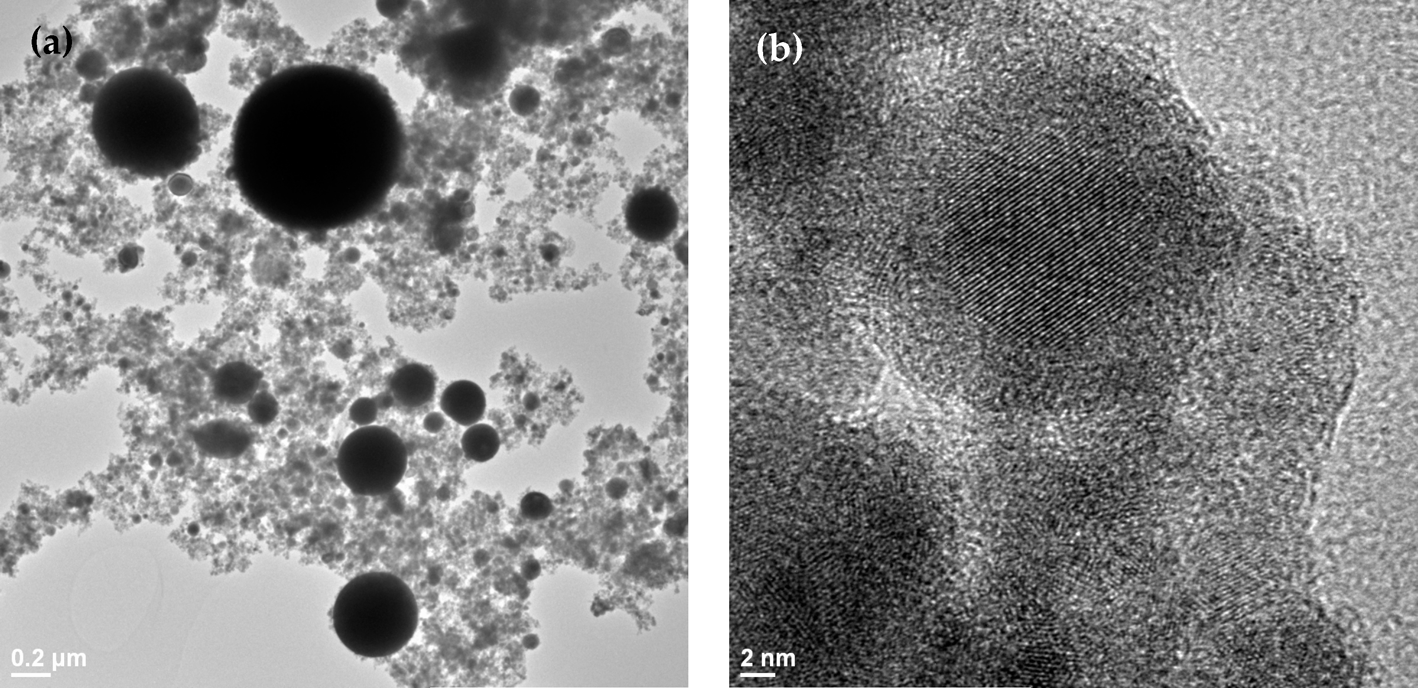

Lithium-ion batteries offer the highest energy density of any currently available portable energy storage technology. By using different anode materials, these batteries could have an even greater energy density. One material, tin, has a theoretical lithium capacity (994 mAh/g) over three-times higher than commercial carbon anode materials. Unfortunately, to achieve this high capacity, bulk tin undergoes a large volume expansion, and the material pulverizes during cycling, giving a rapid capacity fade. To mitigate this issue, tin must be scaled down to the nano-level to take advantage of unique micromechanics at the nanoscale. Synthesis techniques for Sn nanoparticle anodes are costly and overly complicated for commercial production. A novel one-step process for producing carbon-coated Sn nanoparticles via spark plasma erosion (SPE) shows great promise as a simple, inexpensive production method. The SPE method, characterization of the resulting particles, and their high-capacity reversible electrochemical performance as anodes are described. With only a 10% addition of these novel SPE carbon-coated Sn particles, one anode composition demonstrated a reversible capacity of ~460 mAh/g, achieving the theoretical capacity of that particular electrode formulation. These SPE carbon-coated Sn nanoparticles are drop-in ready for present commercial lithium-ion anode processing and would provide a ~10% increase in the total capacity of current commercial lithium-ion cells.