E. White, C. Schlereth, M. Lepple, H. Hattendorf, B. Nowak, M.C. Galetz

Materials and Corrosion (2023), DOI: 10.1002/maco.202213380

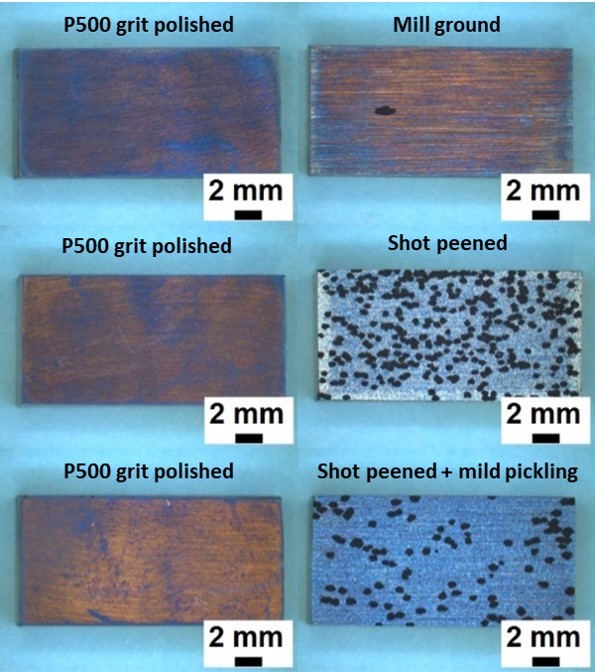

Metal dusting attack is a serious problem in processing industries using carbonaceous gases and high temperatures. Ni-based alloy 699 XA was recently developed as an alloy for these types of environments with high resistance against metal dusting. In this study, different surface treatments of this chromium- and aluminum-rich alloy are shown to have an important influence on the metal dusting onset behavior. It was found that surface treatments that are traditionally considered to be helpful for fatigue performance, for example, shot peening, and pickling were detrimental to the metal dusting performance of alloy 699 XA. Additionally, the shot peening surface treatment promoted Fe surface contamination, resulting in a negative impact on the metal dusting pitting resistance of the alloy. Deformation accompanied by apparent BCC α-Cr precipitation in the bulk microstructure, but a comparison with cold-rolled materials shows that the surface treatment dominates the metal dusting resistance.