A.S. Ulrich, C. Schlereth, B. Grégoire, F. Sutter, C. Oskay, C. Hildebrandt, M.C. Galetz

Solar Energy Materials and Solar Cells 257 (2023), 112382, DOI: 10.1016/j.solmat.2023.112382

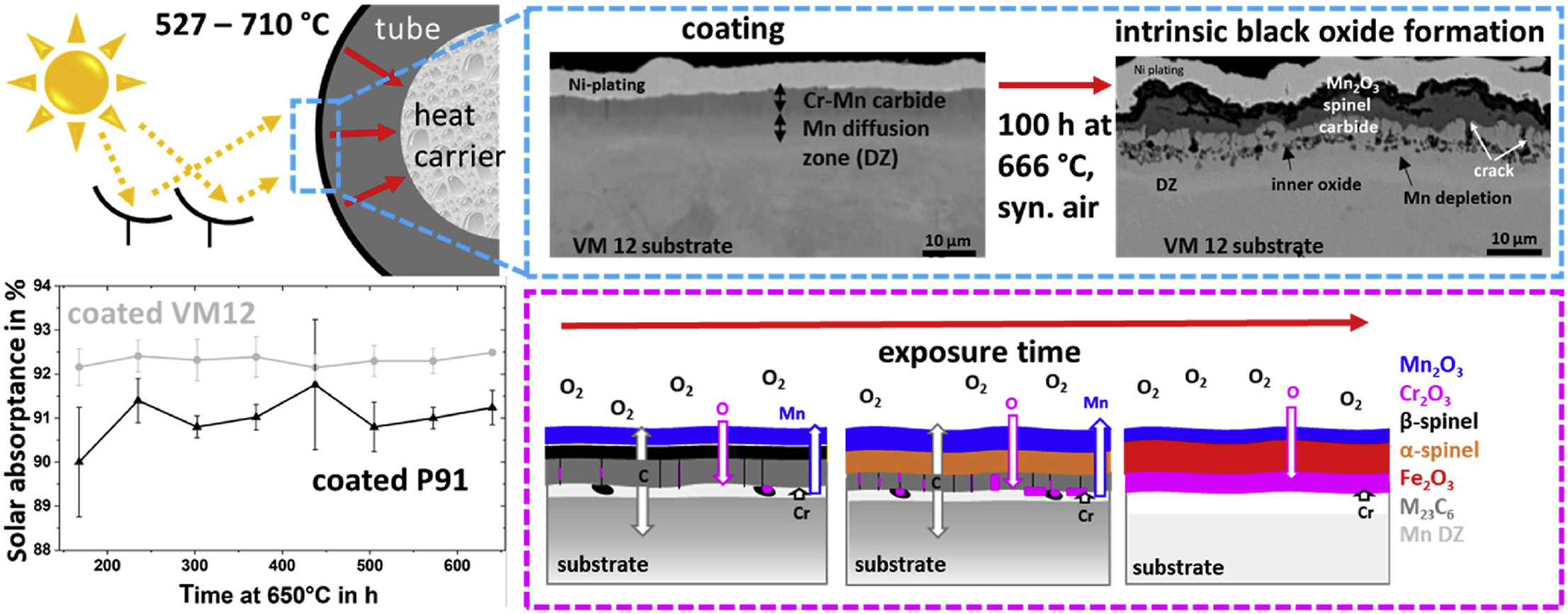

Receiver systems in concentrated solar power plants have to withstand harsh desert conditions and high temperatures, while maintaining high efficiencies converting solar radiation to thermal energy within a heat transfer fluid. The need to improve high absorbing receiver coatings with respect to their lifetime is essential to enhance the economic efficiency of such plants. Diffusion coatings based on Cr and Mn are shown to provide intrinsic self-healing properties forming black Cr–Mn-oxides in situ. Oxidation tests in air are conducted at temperatures between 527 and 710 °C up to 100 h. Thereby, solar absorptances up to 93% and optical coatings efficiencies up to 80% are obtained on coated VM12 steel with the best coating performance shown at around 650 °C. Thermocyclic oxidation for up to 640 h at a maximum temperature of 650 °C proves that there is a slight drop in solar absorptance after around 50 h of exposure, but afterwards it remains stable. Additionally, it is found that coated VM12 performs better in comparison to P91 steel. A mechanism of oxide formation and coating consumption is proposed showing the importance of Mn diffusion on oxide formation. In the beginning of the exposure, Mn2O3 and cubic MnxCr3-xO4 (β-spinel) form, which transform to tetragonal MnxCr3-xO4 (α-spinel) and with continuing exposure also to Cr2O3. For analysis, metallographic investigations are combined with methods such as Raman-spectroscopy, XRD, spectrophotometry, qualitative and quantitative EPMA measurements.