M. Rudolphi, M.C. Galetz, M. Schütze

Journal of Thermal Spray Technology 30 (2021), 694-707, DOI: 10.1007/s11666-021-01163-5

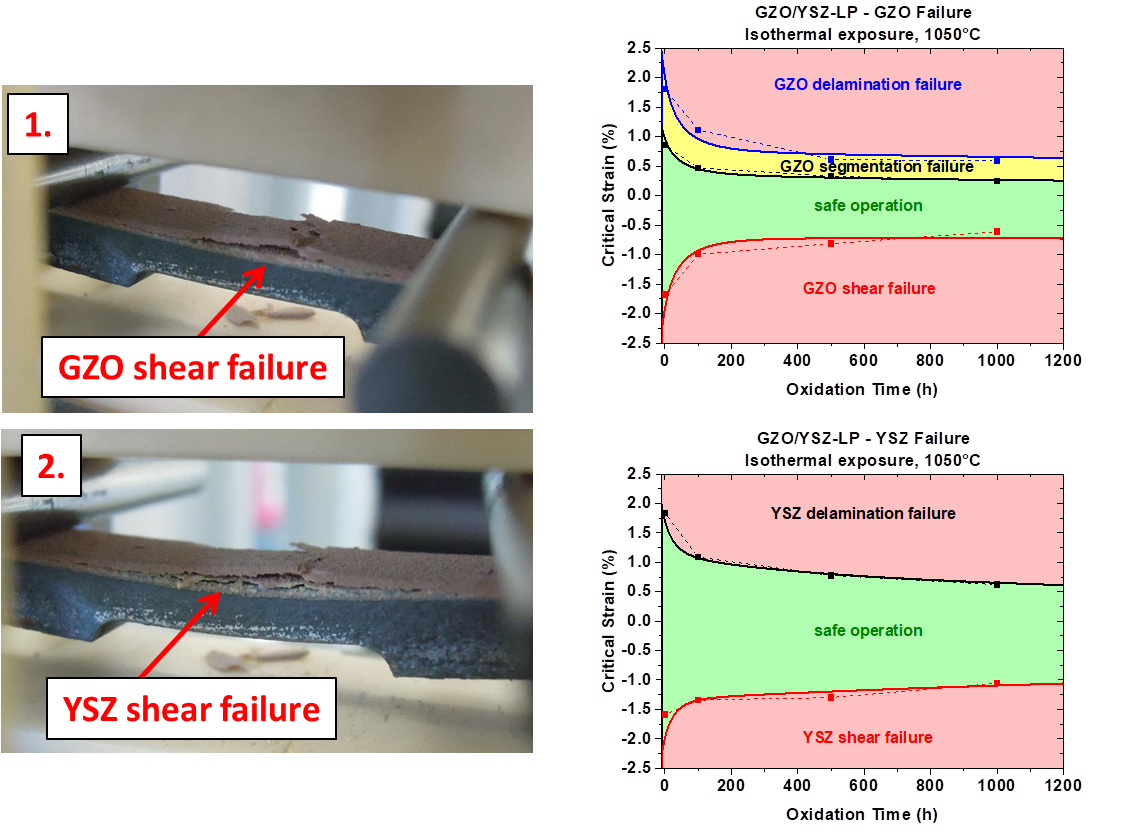

Loss of mechanical integrity due to thermal aging and subsequent spallation of the ceramic top layer is one of the dominant failure mechanisms in thermal barrier coating systems. In order to predict and avoid such mechanical failure, a strain-based lifetime assessment model is presented for a novel double-layer thermal barrier system. The investigated ceramic system consists of a gadolinium zirconate layer on top of a layer of yttria-stabilized zirconia prepared by atmospheric plasma spraying. The mechanical stability diagrams generated by the model delineate areas of safe operation from areas where mechanical damage of the thermal barrier coating becomes imminent. Intensive ceramographic inspection is used to investigate the defect growth kinetics in the ceramic top coat after isothermal exposure. Four-point bending experiments with in situ acoustic emission measurement are utilized to determine the critical strain to failure. The results are then used to generate mechanical stability diagrams for the thermal barrier coatings. From these diagrams, it becomes evident that the gadolinium zirconate layer has significantly lower strain tolerance than the yttria-stabilized zirconia. However, the underlying yttria-stabilized zirconia layer will provide some thermal protection even when the gadolinium zirconate layer has failed.