A. Purwitasari, R. Fetzer, A. Heinzel, C. Oskay, A. Weisenburger, G. Müller

Corrosion Science 255 (2025), 113142, DOI: 10.1016/j.corsci.2025.113142

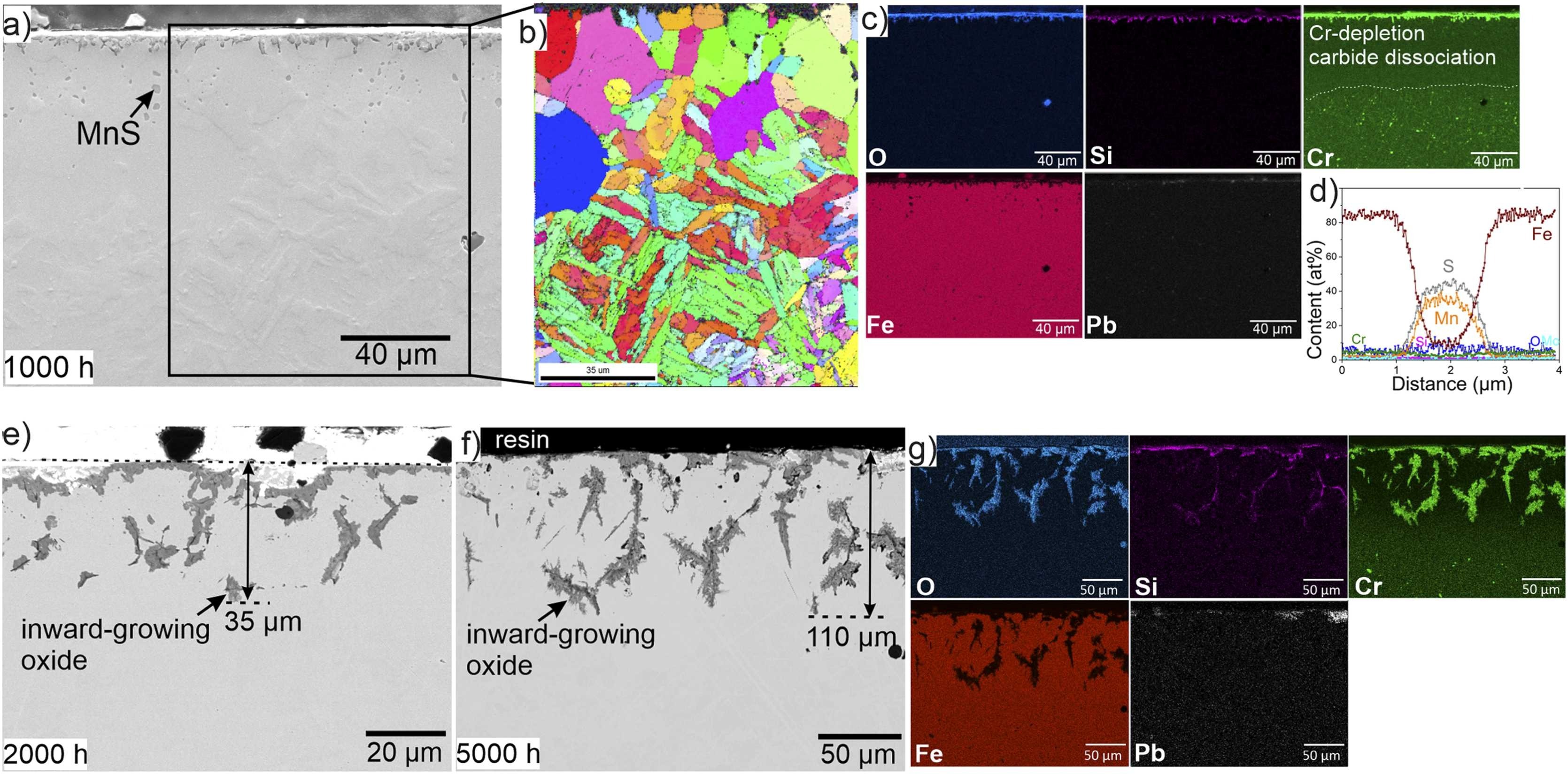

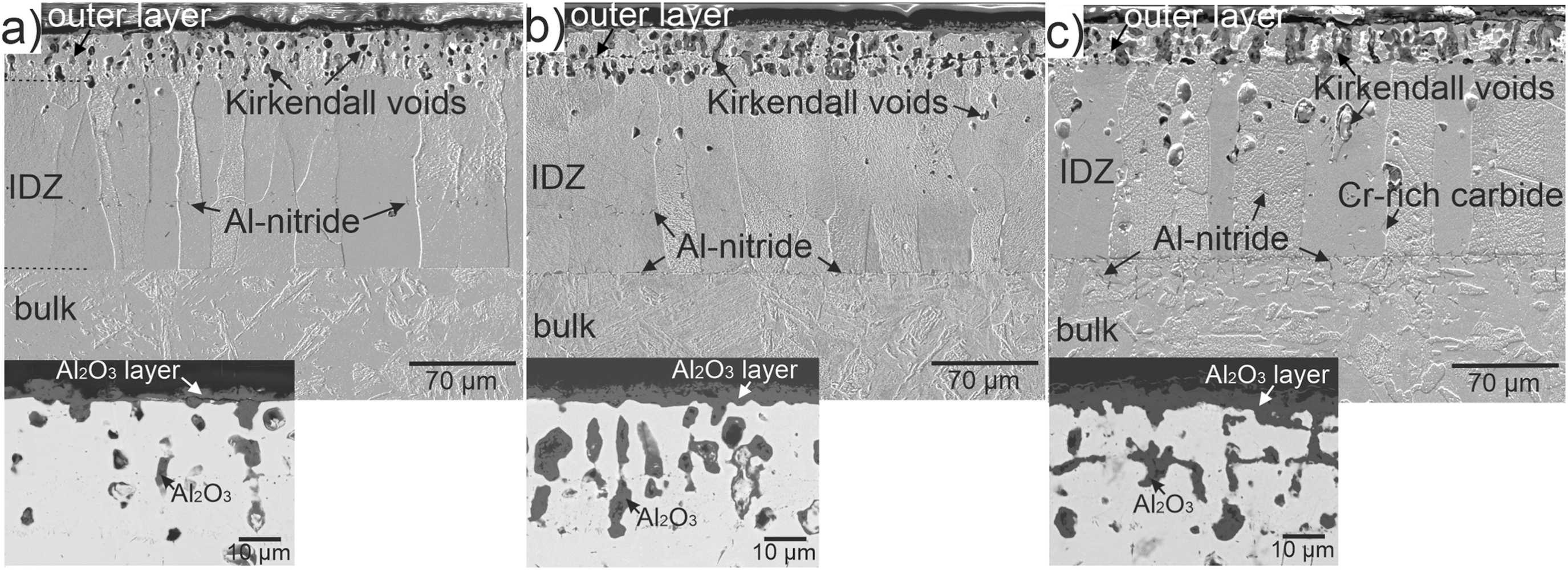

This research investigates the corrosion behavior of three different ferritic/martensitic steels (P91, 1.4748, 1.4136) in liquid lead containing 2 × 10−7 wt% dissolved oxygen. Additionally, one of the steels (P91) is surface-aluminized by pack cementation prior to Pb exposure to explore the efficacy of an aluminide coating. The aim of this study is to explore the possibility to extend the use from a corrosion point of view of the selected F/M steels in liquid Pb up to 700 °C. To gain a better understanding of the corrosion behavior over time, exposure tests with three different durations up to 5000 h are performed. Post-exposure analysis demonstrates oxidation on all materials in the initial stage, followed by various differing scenarios specific for each material and exposure temperature. These range from oxidation with protective properties and selective Cr dissolution with intergranular Pb penetration to total dissolution.