L. Zander, J.P. Zander, T. Blackburn, E.M.H. White, A.J. Knowles, M.C. Galetz

JOM (2025), DOI: 10.1007/s11837-025-07915-w

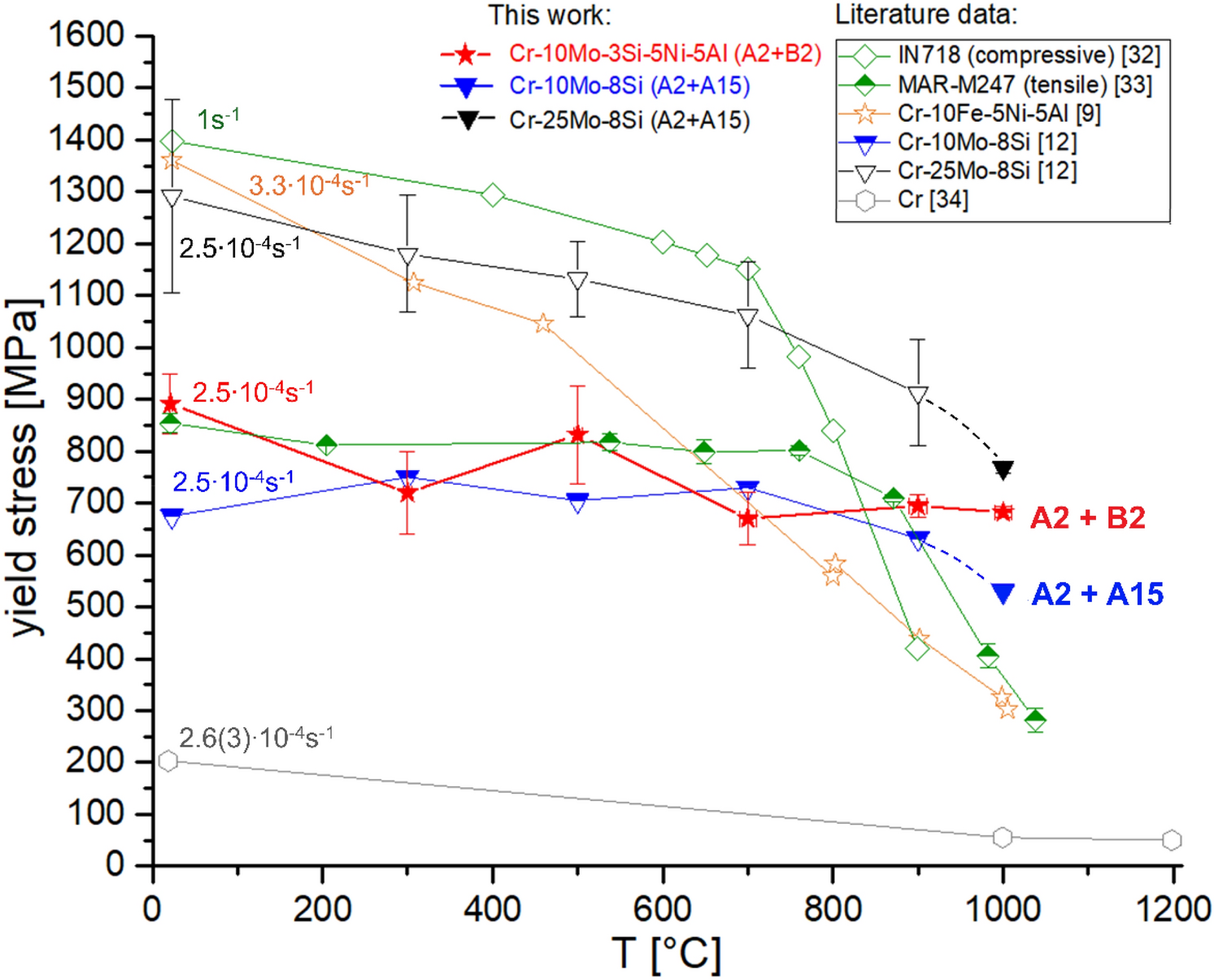

The Cr-Mo-Si-Ni-Al alloy system was investigated with the goal of combining recent advances in the two-phase Cr-Mo-Si system [(Cr,Mo)-A2 matrix + (Cr,Mo)3Si-A15 precipitates], with the approach of strengthening the Cr matrix with the low misfit precipitate NiAl (B2). The role of Mo and Si in the system was investigated in alloys that were arc-melted, annealed, and characterized for microstructure, hardness, fracture toughness, and compressive strength at various temperatures (21–1000 °C). Unlike the A15 phase, the B2 phase does not reduce the fracture toughness of the Cr solid solution matrix. The yield stress of the A2–B2 system is comparable to that of the A2–A15 system, but retains its strength up to higher temperatures (tested up to 1000 °C). The addition of Ni and Al to the Cr-Mo-Si system shifts the stability regime of the σ phase in the system to lower Mo and Si contents and lower temperatures. Since Ni shows high solubility in the σ phase, reducing the Ni/Al ratio reduces the amount of the σ phase. The implementation of NiAl precipitates to the Mo- and Si-strengthened Cr matrix has a beneficial effect on the high-temperature strength and low-temperature fracture toughness of the Cr-based alloys.