J. Bernauer, N.-C. Petry, N. Thor, S.A. Kredel, D.T. Teppala, M.C. Galetz, M. Lepple, A. Pundt, E. Ionescu, R. Riedel

Adv. Eng. Mater.. 26 (2024), 2301864, DOI: 10.1002/adem.202301864

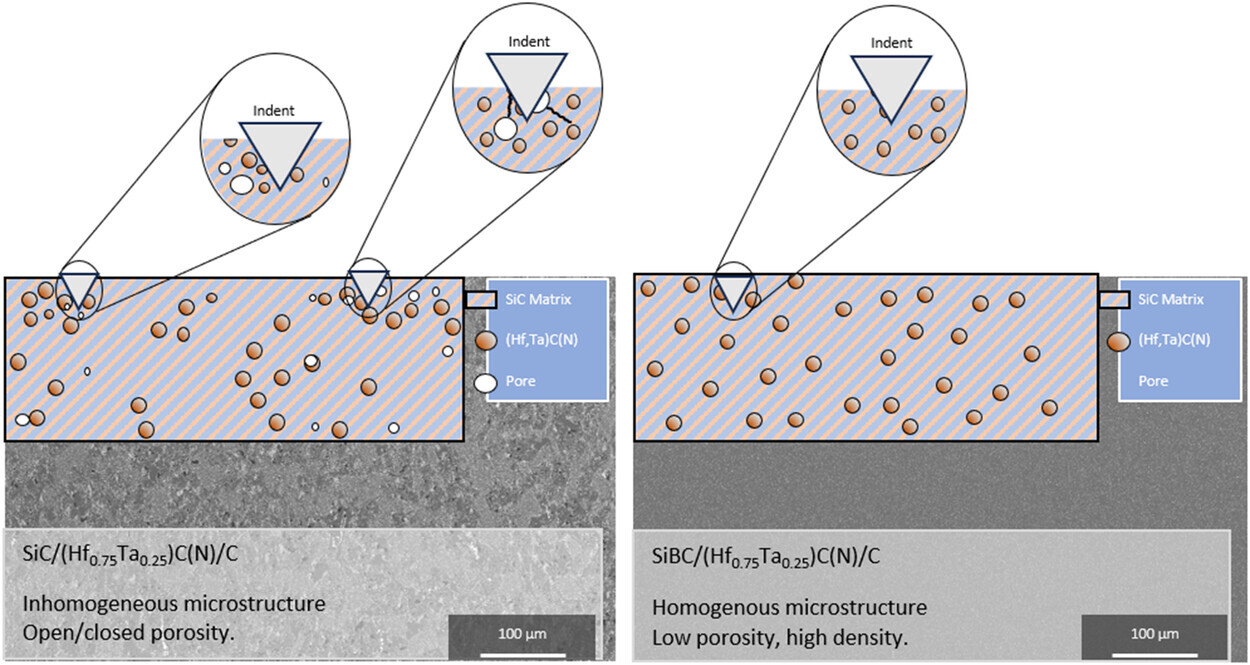

In the present work, monolithic SiC/(Hf0.75Ta0.25)C(N)/(B)C ceramic composites are prepared via spark plasma sintering of amorphous SiHfTa(B)CN-based powders synthesized from single-source precursors. The as-sintered ceramic nanocomposites are investigated by X-ray diffraction, Raman, scanning electron microscopy, and transmission electron microscopy in order to study their microstructure and chemical composition. Furthermore, the thermal conductivity, the thermal expansion, as well as the hardness and Young's moduli of the prepared monolithic samples are determined. The incorporation of boron in the system results in enhanced densification due to decreased porosity and improved distribution of the individual phases in the composite after sintering. These favorable effects also positively influence the thermomechanical properties of the composite. The boron-modified sample displays a decreased thermal diffusivity and conductivity compared with the boron-free sample. Additionally, a macro-hardness obtained by Vickers indentation of 31 GPa is achieved for loads up to 196 N, surpassing the hardness of ultrahard materials like silicon carbide, hafnium carbide, and tantalum carbide as well as their solid solutions. Young's moduli of the composites were analyzed to 405 ± 10 and 277.5 ± 41 GPa for the boron-containing and boron-free samples, respectively.