T. König, B. Burek, M.C. Galetz

Journal of the European Ceramic Society 44 (2024), 841-849, DOI: 10.1016/j.jeurceramsoc.2023.10.001

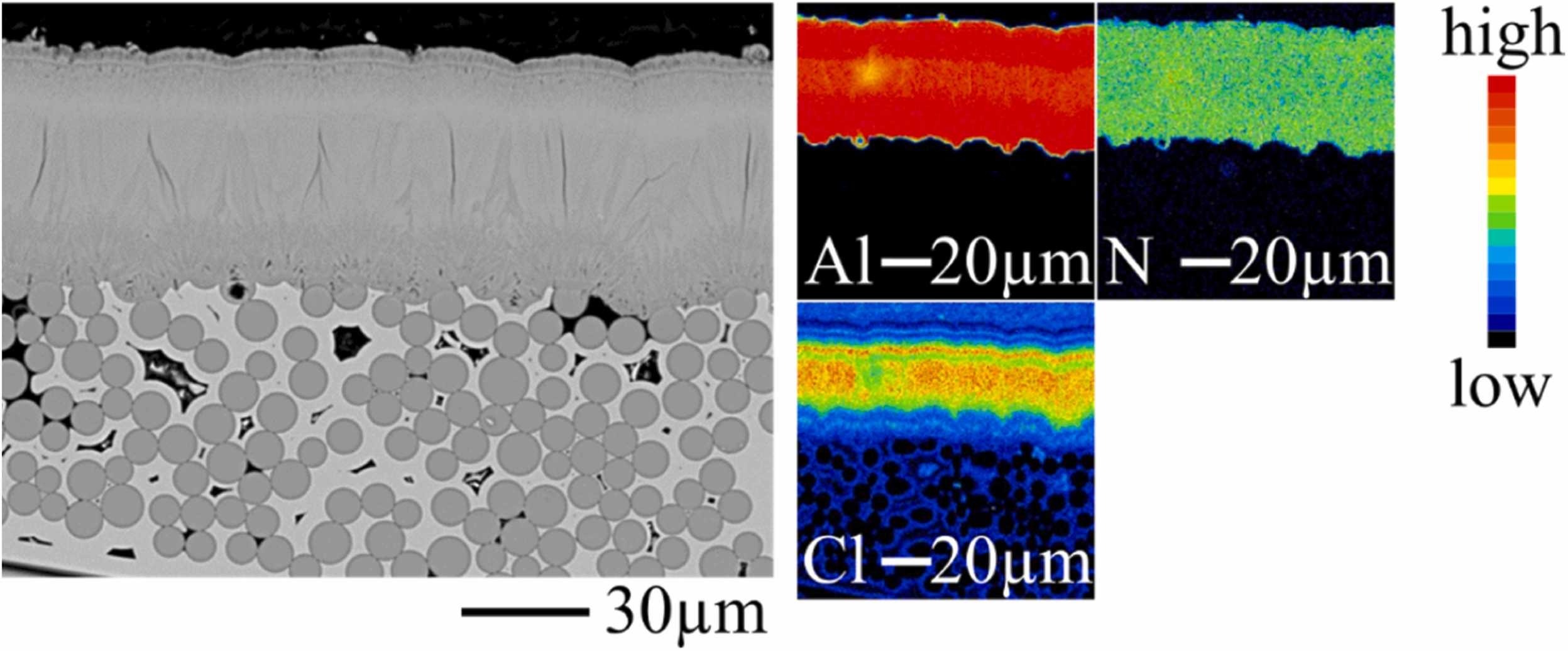

Aluminum nitride is discussed for different high temperature applications, due to its unique properties. Lately it also received attention as a coating for different substrate materials. Within the present study oriented AlN-coatings with two different crystal orientations were produced via reactive magnetron sputtering and a high temperature CVD process on SiC-based substrates. The oxidation resistance of these coatings in comparison to bulk AlN was investigated in wet synthetic air at 1200 °C. Both, the bulk AlN and (101̅0)-oriented AlN-coating formed a porous Al2O3-scale, which was not protective and resulted in high oxidation rates. In contrast, the (0001)-oriented coatings were able to form a thin oxide scale and remained protective for the total exposure time of up to 200 h at 1200 °C. The underlying mechanism of the oxidation of AlN in wet air was discussed, considering the strong influence of the crystal orientation.