The Materials and Corrosion division addresses materials issues of the energy and process technology sectors. The use of chemistry and energy based pedominantly on renewable resources comes with extreme corrosive, thermal and mechanical stresses for the materials. This presents numerous challenges for the researchers at DFI to develop solutions for the energy transition.

The division consists of four teams that work in their own research fields but in close collaboration with each other:

The demand for environmentally and resources-friendly processes as well as higher efficiency in thermal plants and machinery requires an increase of operating temperatures. However, processes conducted at high temperatures and often in complex atmospheres lead to increasing demands on the high temperature corrosion resistance of the materials used. The main research objectives of the "high temperature corrosion" team at DFI are material analysis and development in the field of aggressive, high temperature environments. Within this research field, we focus on the development of metallic and ceramic protective coatings and innovative material systems appropriate for extremely aggressive service conditions (e.g. chlorine, sulphur, bromine, vanadium, and carbon-rich environments) and operation temperatures up to 1800 °C. The team also works on conceptionalising, developing and producing novel alloying systems that withstand more aggressive conditions.

Computational modelling of coatings and their lifetime: prediction of material behaviour during manufacturing as well as their lifetime during operation at high temperatures.

Examples: modelling of layer growth and phase formation in the pack cementation process, modelling the influence of defects on the mechanical properties of thermal barrier coatings and oxide layers.

Functional high temperature coatings: combining high temperature protective coatings with additional properties such as self-cleaning, thermal insulation or improved aerodynamics.

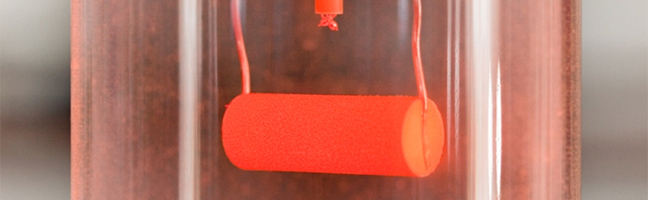

Examples: self-healing "shark skin" coatings for turbines, foam-like ceramic thermal barrier coatings.

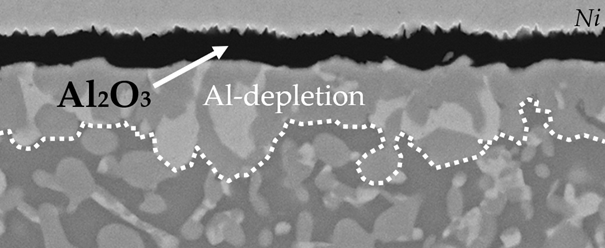

"Minimally-invasive" high temperature corrosion protection: targeted changes in the chemical  composition near the surface for improved corrosion behaviour at high temperatures.

composition near the surface for improved corrosion behaviour at high temperatures.

Examples: development of stable and protective alumina layers by using the halogen effect, Sn-modified surfaces for catalytic poisoning in metal dusting environments, controlling chlorine corrosion by selective doping of coatings.

Achieving a carbon-neutral economy requires increased efficiencies of green technologies and thus increases the demand on materials to reach higher operating temperatures and survive more aggressive conditions. The aerospace, transportation, process and energy industries, among others, are desperate for alloys that can endure high temperature and extreme (HX) environments. The “High Temperature Alloys” team at DECHEMA Research Institute designs, develops and produces such alloys and coatings. We optimize alloy oxidation and corrosion resistance in addition to mechanical properties, analyzing microstructure, heat treatment and processing (additive manufacturing, AM) influences.

The research team focusses on the one hand on the mechanistic investigation of corrosion processes of new materials as well as in various technologies. On the other hand the focus is on corrosion protection by different types of coatings. In both fields light alloys (aluminium, magnesium, titanium as well as high-strength steels) play an important role. Furthermore actual topics in the field of cathodic protection are adressed. Most profiting industrial branches are automotive, aviation, medical technologies, the structural-facings sector and pipeline construction.In addition the research team is responsible for corrosion investigations, materials selection tasks and corrosion failure analysis in the frame of the DECHEMA Corrosion Center.

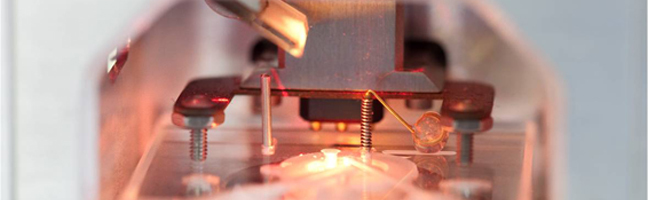

Development of inorganic coating systems via anodising, application of ultrasound and use of nanoparticles or nanocapsules (see projects PhotoEloxal, MagPEO2, PEO-TBC, AlUlIMP)

Antimicrobial surfaces and biocorrosion (see project Antimicrobial Peptides)

Mechanistic corrosion investigations and modelling (see projects AC-Corrosion, Al-Grinding, SLM-Titanium)

Electrochemical measurements

Materials characterisation methods

Spectroscopic/analytical methods

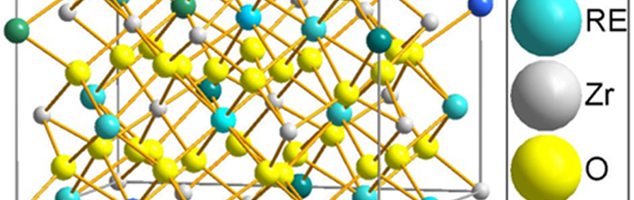

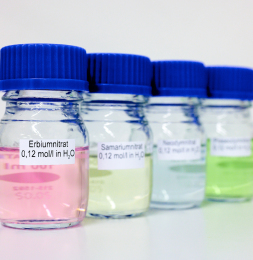

New materials that are stable at high temperatures in aggressive atmospheres over long periods of time are needed for more efficient and low-emission gas turbines, e.g. for aircrafts. Multicomponent equiatomic oxides (MEO), or high entropy oxides (HEO), are a promising new class of materials for this purpose, as they combine stability at high temperatures and low thermal conductivity. In addition, other attractive characteristics, such as ionic conductivity, reversible lithium storage, catalytic activity, and dielectric and magnetic properties, make HEOs an interesting class of materials.

Synthesis of novel compositions using wet-chemical methods and solid phase sintering

Synthesis of novel compositions using wet-chemical methods and solid phase sintering

Are our research topics of interest for you, or can we assist you with our comprehensive analytical capacity?

The DECHEMA Corrosion Center provides more information and contact options.

Assoc. Prof. Dr.-Ing. Mathias Galetz

Telephone +49 69 7564-397

Telephone +49 69 7564-606

Telephone +49 69 7564-602

Telephone +49 69 7564-398

Telephone +49 69 7564-492