B. Feng, A.K. Fetzer, A.S. Ulrich, M.C. Galetz, H.-J. Kleebe, E. Ionescu

Journal of the American Ceramic Society 105 (2022), 99-110, DOI: 10.1111/jace.18038

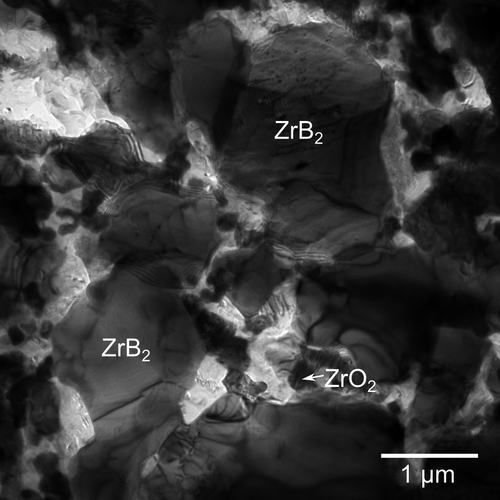

In the present work, dense ZrB2-based monoliths were produced via hot-pressing of ZrB2 powders coated with amorphous polymer-derived SiCN, SiZrCN, or SiZrBCN at relatively moderate temperatures (i.e., 1800℃). Thus, ZrB2 particles were embedded in polymer-derived ceramic shell were realized by coating their surface with the corresponding polymeric precursors (polysilazane, Zr-modified polysilazane, Zr- and B-modified polysilazane, as for SiCN, SiZrCN, and SiZrBCN; respectively), followed by cross-linking at 200℃ and pyrolysis at 1100℃ in Ar atmosphere. The obtained monolithic samples were carefully characterized concerning their phase composition and microstructure. Typically, the densified samples exhibit a homogeneous microstructure consisting of ZrB2 grains and a multi-phasic polymer-derived ceramic grain boundary phase (β-SiC, t-BCN, ZrO2, and ZrC). The prepared monoliths exhibited fair hardness values, that is, 12.5, 14.2, and 13.3 GPa for ZrB2/SiCN, ZrB2/SiZrCN, and ZrB2/SiZrBCN.