D. Kniep, M. Rudolphi, K. Ohla, A. Frehn, M.C. Galetz

npj Materials Degradation 9 (2025), DOI: 10.1038/s41529-025-00608-4

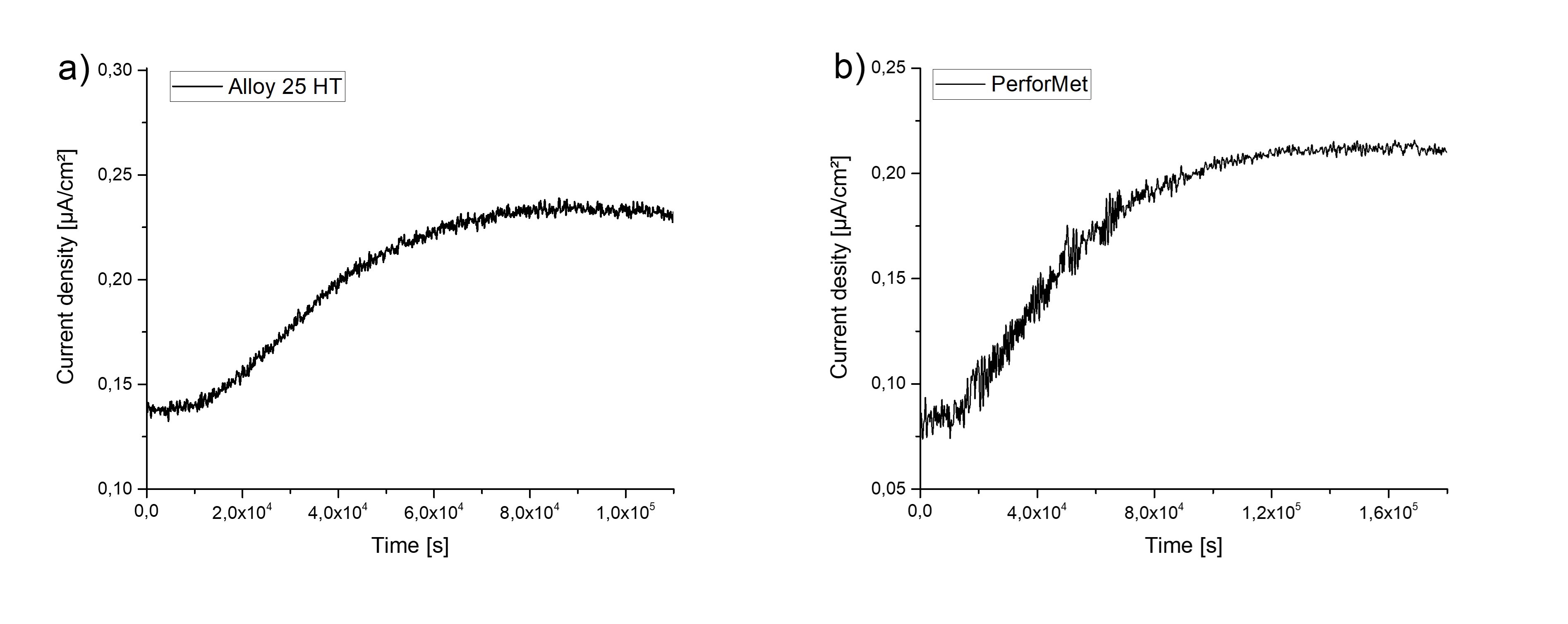

The usage of high-strength materials in hydrogen-containing atmospheres is a particular challenge. High-strength copper alloys, which have not been extensively studied, may offer significant potential. In this study, the hydrogen solubility, diffusivity, and embrittlement of two high-strength copper-based alloys, Alloy 25 HT and PerforMet AT, are investigated compared to austenitic stainless steel 316 L. Across all charging conditions, the steel 316 L absorbed multiple orders of magnitude more hydrogen than the copper alloys. Permeation tests reveal effective diffusion coefficients of 1.7 × 10−13 m²/s for Alloy 25 HT and 3.0 × 10−14 m²/s for PerforMet AT at 60 °C, respectively. Results of charged tensile specimens in slow strain rate tests indicated a negligible reduction of strain for Alloy 25 HT and a minor reduction to 83.5% of the strain of the uncharged PerforMet AT, suggesting a low susceptibility to hydrogen embrittlement under these tested conditions.