S. Hagen, K. Beck, D. Kubacka, H.-E. Zschau, M.C. Galetz, E. Spiecker, S. Virtanen

Oxidation of Metals 97 (2022), 209-226, DOI: 10.1007/s11085-021-10087-y

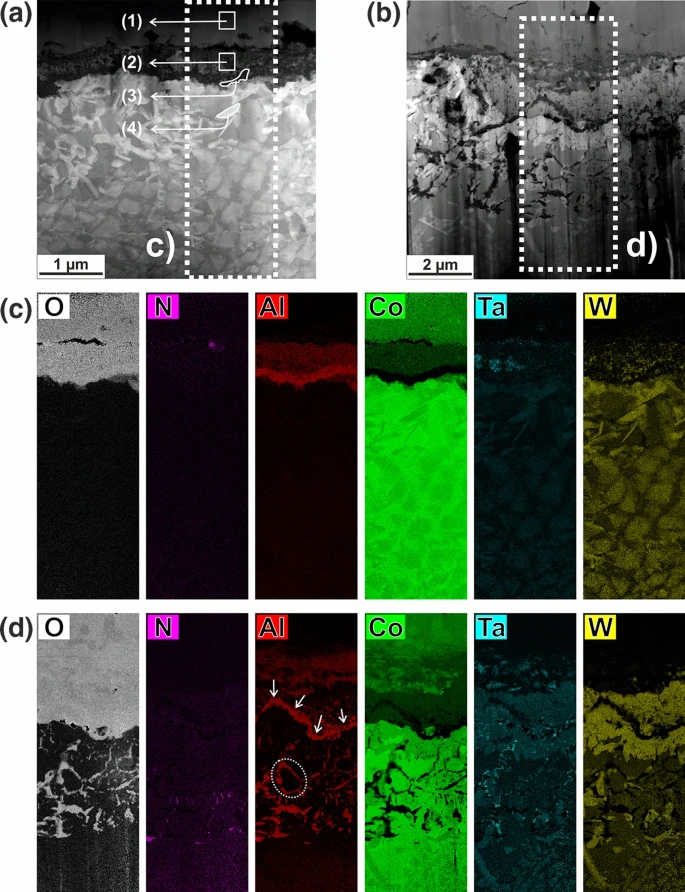

The oxidation resistance of novel γ/γ’-strengthened Co-base superalloys is clearly outmatched by their Ni-base counterparts within the high-temperature regime. Therefore, surface modification strategies to foster protective alumina growth seem auspicious. This study elucidates the impact of fluorination and shot-peening on protective alumina formation at 900 °C for a quaternary Co-base model alloy (Co-Al-W-Ta system) which is well known for an exceptionally low inherent oxidation resistance. Time-resolved isothermal gravimetric analysis (TGA) in synthetic air, detailed electron microscopic analysis, and X-ray diffraction (XRD) were used. For polished samples, no pronounced enhancement of oxidation resistance could be obtained by halogenation. However, in case of shot-peened samples (halogen-free), an increased tendency for alumina formation is found compared to polished surfaces. The very early stages of oxidation were identified to be especially crucial with respect to sustainable protective scale growth. Most noteworthy is the observation of a strong synergistic effect derived by a combination of halogenation and shot-peening, leading to significantly increased oxidation resistance.