K. Beck, F. Hinrichs, C. Oskay, A.S. Ulrich, M. Heilmaier, M.C. Galetz

Coatings 13 (2023), 1712, DOI: 10.3390/coatings13101712

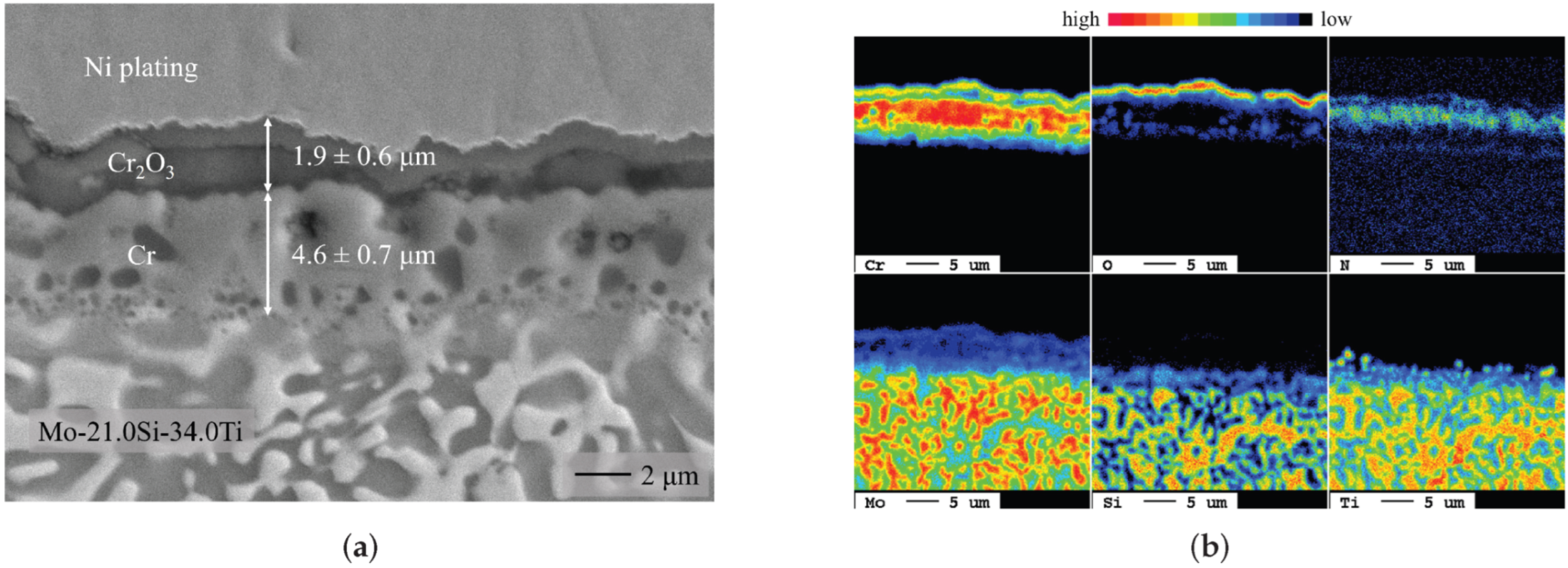

The oxidation behavior of two ternary Mo-Si-Ti alloys (eutectic Mo-20.0Si-52.8Ti and eutectoid Mo-21.0Si-34.0Ti) was investigated using thermogravimetric analysis at 700 °C, 900 °C, and 1300 °C for 100 h. The eutectic alloy formed a protective SiO2/TiO2 oxide scale, whereas the eutectoid alloy showed catastrophic oxidation. To improve the oxidation behavior of these alloys, chromium diffusion coatings deposited via pack cementation on the surface were investigated. Cr coatings were found to be suitable for improving oxidation resistance at 700 °C and 900 °C but failed at 1300 °C due to the evaporation of thin scales. At 700 °C and 900 °C, the formation of a Cr2O3 scale was proven on the Ti-rich/Mo-lean eutectic composition. After exposure, the Ti-lean/Mo-rich eutectoid composition, which is intrinsically more prone to oxidation, was found to form a continuous Cr2O3 scale only at 700 °C.