03ET7012D

| Laufzeit: | 01.01.2014 - 31.12.2018 |

|---|---|

| Geldgeber: | Bundesministerium für Wirtschaft und Energie (BMWi) |

| Bearbeiter: | Dr. Mario Rudolphi, Dr. habil. Xabier Montero |

| Arbeitsgruppe: | Hochtemperaturwerkstoffe |

Conventional coal-fired power plants are still an important pillar in energy industry to supply the base-load energy when wind and solar power are not sufficiently available. In an effort to reduce consumption of limited fossil fuels, co-firing of biomass has become more and more common. While co-firing reduces the CO2 footprint of the plant, it also introduces higher amounts of corrosive species such as chlorine and sulfur into the system. Consequently, higher corrosion rates and material loss are observed in the firing chamber components. Especially superheater tubes are subjected to increased corrosive attack and are prone to early replacement.

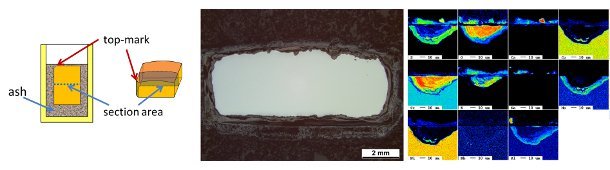

Several materials are selected for exposure experiments in order to clarify the role of sulfur- and chlorine-containing salts on the hot corrosion attack. The investigated materials cover a broad range of commercially available alloys, from nickel-based to iron-based materials. Testing is performed with the specimens embedded in artificial ash and in fire-side simulating atmosphere containing SO2 and HCl.

zurück

Gefördert vom Bundesministerium für Wirtschaft und Energie (BMWi)

Dr. Mario Rudolphi

Tel.: 069 / 7564-492

E-Mail: mario.rudolphi

T. König, X. Montero, M.C. Galetz, Materials and Corrosion 71 (2020), 1138

X. Montero, A. Ishida, M. Rudolphi, H. Murakami, M.C. Galetz, Corrosion Science 173 (2020), 108765

T. König, X. Montero, M.C. Galetz, Materials and Corrosion 70 (2019), 1371

X. Montero, M. Rudolphi, M.C. Galetz, Materials and Corrosion 70 (2019), 2179