GL 181/45, GA 1704/2

| Period: | 2016-03-01 to 2019-02-28 |

|---|---|

| Partner: | Chair of Metals and Alloys, University Bayreuth |

| Funder: | German Research Foundation (DFG) |

| Project Coordinator: | Anke Silvia Ulrich |

| Research Group: | High Temperature Materials |

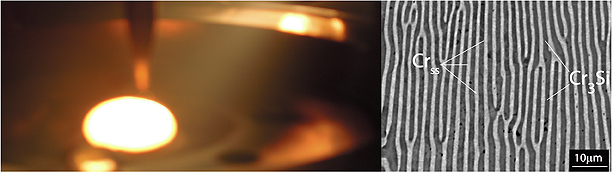

Recently, refractory alloys have received increasing attention for the purpose of substituting Ni-based single crystal superalloys in high temperature applications. Cr-based alloys are promising candidates next to other refractory alloys such as Mo-Si-B, Co-Re, and Nb-Si alloys. They offer higher melting points (T > 1700°C), and have densities lower than those of Ni-based superalloys. However, challenges such as nitrogen embrittlement at high temperatures, reduced oxidation resistances at ultra-high temperatures (T > 1000°C), and lack of room temperature ductility have hindered the development of Cr-based alloys.

In our earlier DFG-supported project, oxidation and nitridation resistance of chromium was improved by addition of Si and Ge leading to higher oxidation resistance and suppressed nitridation at high temperatures.

This project is a cooperation between DECHEMA-Forschungsinstitut (DFI) and the Chair of Metals and Alloys at University of Bayreuth (MW). It is aimed to develop heat treatable Cr alloys with Cr contents higher than 88 at.% and to optimize their microstructure via intermetallic precipitations. The influence of a heat treatment process on microstructural evolution, mechanical properties, and oxidation behaviour of alloys will be studied. Mechanical testing such as creep tests and fracture toughness measurement will be carried out. Furthermore the alloying capacity of the system is investigated by adding molybdenum and platinum to the Cr-Si-Ge system.

back

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) - GL 181/45, GA 1704/2

PD Dr. Mathias Galetz

Telephone +49 69 / 7564-397

E-mail: mathias.galetz

A.S. Ulrich, P. Pfizenmaier, M. Kerbstadt, L. Pelchen, A. Solimani, U. Glatzel, M.C. Galetz, Advanced Engineering Materials 2401818 (2025)

P. Pfizenmaier, A.S. Ulrich, M.C. Galetz, U. Glatzel, Metals 11 (2021), 1072

A.S. Ulrich, U. Glatzel, M.C. Galetz, Oxidation of Metals (2021)

A.S. Ulrich, Schriftenreihe des DECHEMA-Forschungsinstituts, Universität Bayreuth, Shaker Verlag, 2020

A.S. Ulrich, P. Pfizenmaier, A. Solimani, U. Glatzel, M.C.Galetz, Corrosion Science 165 (2020), 108376

P. Pfizenmaier, A.S. Ulrich, M.C. Galetz, U. Glatzel, Intermetallics 116 (2020), 106636

A.S. Ulrich, T. Kaiser, E. Ionescu, R. Riedel, M.C. Galetz, Oxidation of Metals 92 (2019), 281

A.S. Ulrich, P. Pfizenmaier, A. Soleimani-Dorcheh, U. Glatzel, M.C. Galetz, International Journal of Refractory Metals and Hard Materials 76 (2018), 72