GRK2561/1

| Period: | 2020-04-01 to 2024-10-31 |

|---|---|

| Partners: | Karlsruhe Institute of Technology, Technical University of Darmstadt |

| Funder: | German Research Foundation (DFG) |

| Project Manager: | Lukas Korell |

| Division: | Materials and Corrosion |

| Team: | High Temperature Alloys |

The Research Training Group 2561 “Material Compounds from Composite Materials” is funded by the German Research Foundation (DFG) and comprises 12 PhD students from 3 research institutes: DECHEMA-Forschungsinstitut (DFI), Technical University of Darmstadt (TUD) and Karlsruhe Institute of Technology (KIT).

The Research Training Group aims to develop, characterize and model new composite materials for high-temperature application beyond 1300°C. This allows for a higher working temperature of combustion engines thus increasing performance and efficiency. Therefore, materials are required which can withstand harsh working environments. The underlying idea is to combine two material systems (composite materials) into material compounds, thereby combining their respective intrinsic characteristics and advantages.

Industrial high-temperature environments are characterized by a mixture of different reactive species, causing complex corrosion attacks. A particularly severe attack is induced by deposits of solid or liquid salts on the surface of compounds. These deposits usually are the result of impurities in combustion atmospheres. Oxygen, sulphur, calcium and sodium are of primary importance due to their ability to form sulphur dioxide, sulphur trioxide or sulphates. Corrosion processes involving salts, such as sulphates, are known as hot corrosion. These mechanisms have barely been researched for silica-formers so far.

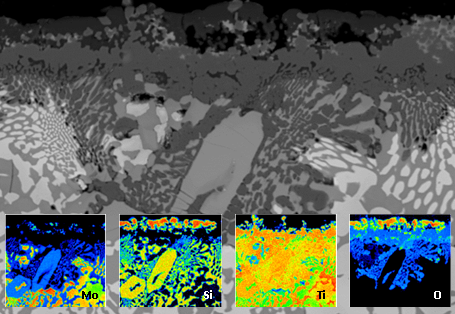

Therefore, the aim is to systematically research the corrosion behaviour of Mo-Si-Ti-(B)-substrates in order to develop a fundamental understanding of the underlying mechanisms. To this end, refractory bulk-materials will be exposed first without and then with deposits consisting of Na2SO4 or CaSO4/CaO in controlled SO2-containing gas atmospheres. Building upon this, protective layer concepts such as Environmental Barrier Coatings (EBCs) using polymer-derived ceramic nanocomposites (PDC-NCs) will be evaluated. The new findings will enable the improvement of the corrosion behaviour of these bulk-materials by applying corrosion-protective coatings.

The bulk materials are supplied by other subprojects of the research training group. The observed corrosion attacks will be microstructurally evaluated and thermodynamically modelled jointly with other PhD students of the group in order to develop a comprehensive understanding of the underlying corrosion mechanisms.

Further information can be found on the GRK website

back

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) - GRK2561/1

Lukas Korell

Tel.: +49 69 / 7564-428

E-mail: lukas.korell

K. Beck, T. König, A. Case, C. Oskay, M.C. Galetz, Mater. Corros. (2024), 1-10

K. Beck, A.S. Ulrich, N. Thor, C. Oskay, M.C. Galetz, International Journal of Refractory Metals and Hard Materials 121 (2024), 106626

K. Beck, A.S. Ulrich, A.K. Czerny, E.M.H. White, M. Heilmaier, M.C. Galetz, Surface and Coatings Technology 476 (2024), 130205

K. Beck, F. Hinrichs, C. Oskay, A.S. Ulrich, M. Heilmaier, M.C. Galetz, Coatings 13 (2023), 1712

F. Hinrichs et al., Corrosion Science 207 (2022), 110566