A. Donchev, L. Mengis, A. Couret, S. Mayer, H. Clemens, M.C. Galetz

Intermetallics 139 (2021), 107270, DOI: 10.1016/j.intermet.2021.107270

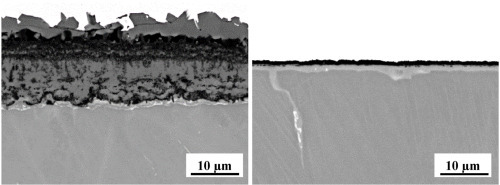

Current limitations to a wider use of intermetallic TiAl alloys in aircraft and automotive engines arise from an insufficient oxidation resistance at temperatures above approximately 800 °C. In this paper, the high temperature oxidation behavior of three engineering γ-TiAl-based alloys at 900 °C in air is reported. The performance of the TNM alloy (Ti-43.5Al–4Nb–1Mo-0.1B), the 4822 alloy (Ti–48Al–2Cr–2Nb), and the Nb-free IRIS alloy (Ti–48Al–2W-0.08B) is compared (all chemical compositions are given in at.%). During testing in air non-protective mixed oxide scales developed on all untreated samples, but with different compositions and thicknesses. These different oxide layers are characterized and their formation mechanisms are discussed. The presence of W in the IRIS alloy leads to a better oxidation behavior compared to untreated TNM and 4822. This behavior was changed in the direction of a protective alumina layer formation via the so-called “fluorine effect”. The above-mentioned alloys were treated with fluorine via a liquid phase process by evenly spraying a fluorine containing polymer on all faces of the specimens. The oxidation resistance of the fluorine treated samples was significantly improved compared to the untreated specimens. Due to the fluorination all treated test coupons exhibited slow oxidation kinetics. The results of isothermal as well as thermocyclic exposure tests are presented and discussed in the view of the chemical composition and processing conditioned microstructure of the three investigated γ-TiAl-based alloys.