C. Schlereth, M.C. Galetz

Oxidation of Metals 96 (2021), 3-15, DOI: 10.1007/s11085-021-10036-9

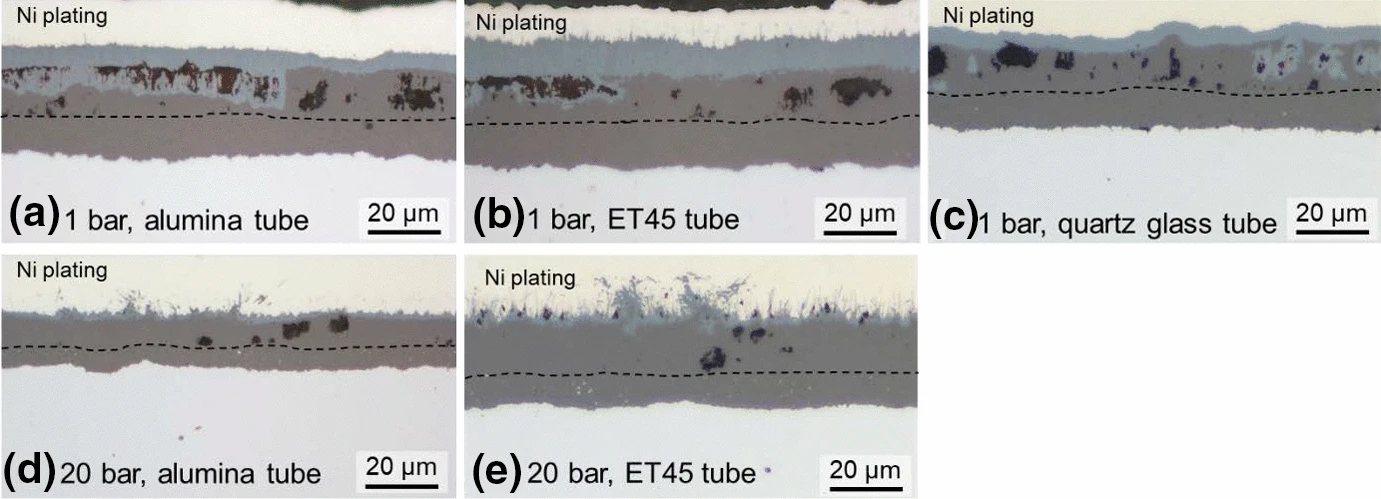

Oxidation of the Fe-base alloy T22 in humid air at 500 °C was investigated. The samples were exposed for up to 1000 h at 1 bar and 20 bar. The influence of three furnace tube materials, alumina, ET45 and quartz glass, on the oxide scale morphology was investigated. Samples and their cross sections were examined using optical microscopy, scanning electron microscopy, electron probe micro analysis and Raman spectroscopy. Multilayered oxide scales consisting of hematite, magnetite and Fe–Cr spinel were found on all samples. However, the composition and morphology of the oxide scales depend on the furnace tube material and on the system pressure. The system pressure is assumed to change the reaction equilibria and adsorption rates. The tube material changed the initial gas composition by formation of volatile Cr species. This volatilization rate increased at higher system pressures.