L. Mengis, C. Oskay, N. Laska, M.C. Galetz

Intermetallics 163 (2023), 108039, DOI: 10.1016/j.intermet.2023.108039

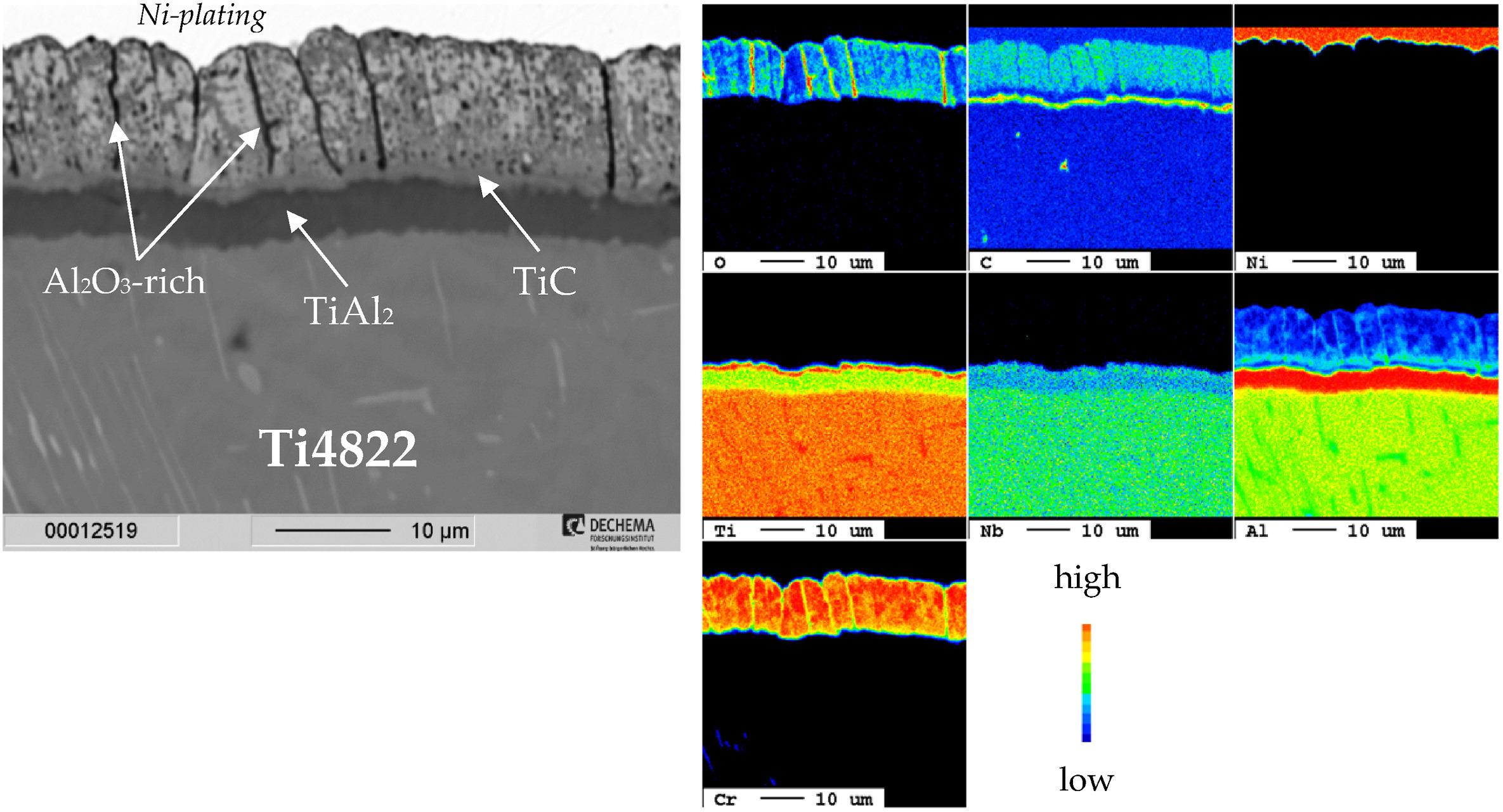

In this study, the oxidation resistance of a Cr2AlC-based MAX-Phase coating on the Ti–48Al–2Cr–2Nb (at. %) alloy was investigated at 700 °C and 800 °C in air. Coatings were synthesized by a combination of DC magnetron sputtering and ex-situ annealing in Ar. The oxidation resistance of the TiAl alloy was greatly improved due to the formation of a protective Al2O3/Cr2O3-scale at both temperatures. During oxidation Al diffuses from the coating into the substrate triggered by the higher Al activity of the Cr2AlC-phase compared to the TiAl substrate. Due to the severe Al-depletion Cr7C3, Cr23C6 as well as Cr2Al become the predominant phases in the coating. As a result of this, the very promising mechanical properties of the coated samples were negatively influenced by the brittle nature of such phases leading to a decrease in the fracture strain.