B. Grégoire, X. Montero, M.C. Galetz, G. Bonnet, F. Pedraza

Corrosion Science 216 (2023), 111092, DOI: 10.1016/j.corsci.2023.111092

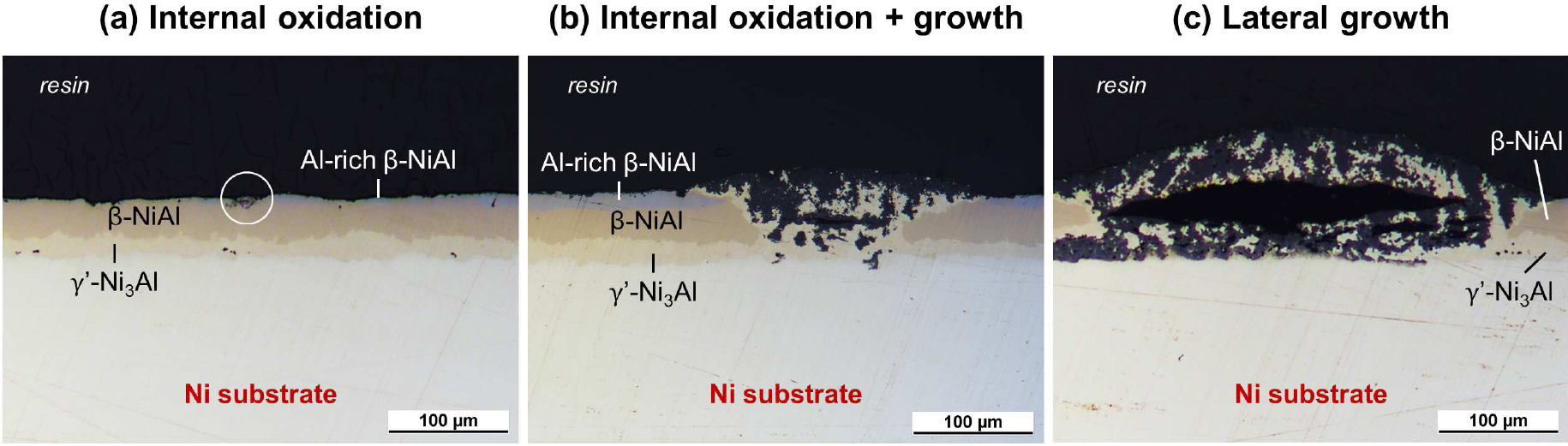

A water-based slurry aluminide coating was elaborated on high-purity nickel and tested in synthetic air, synthetic air + 0.5 % SO2/SO3 and synthetic air + 0.5 % SO2/SO3 with sodium sulphate (Na2SO4) deposit at 700 °C. The developed coating considerably increased the oxidation-sulphidation resistance of nickel in the absence of salt through the formation of thin and adherent alumina scales. In contrast, the presence of sodium sulphate decreased the corrosion resistance. Microstructural investigations indicated that aluminium depletion and the related formation of Ni-rich oxides is mainly responsible for the onset of the corrosion attack following sulphation reaction and fluxing mechanisms.