K. Beck, A.S. Ulrich, A.K. Czerny, E.M.H. White, M. Heilmaier, M.C. Galetz

Surface and Coatings Technology 476 (2024), 130205, DOI: 10.1016/j.surfcoat.2023.130205

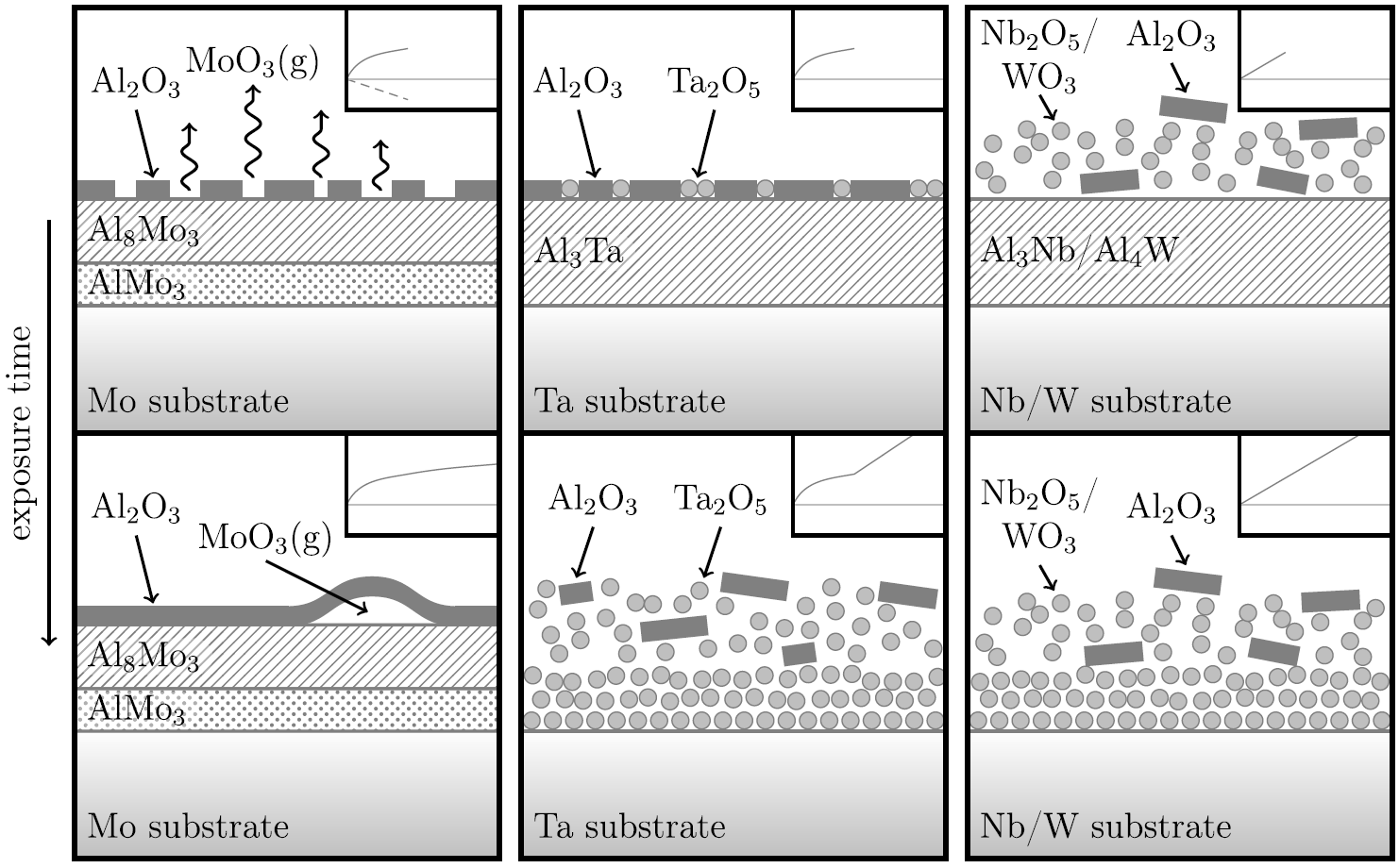

Refractory metal based alloys show great potential as structural materials for high-temperature applications due to their high melting points, but they are prone to catastrophic oxidation at around 700°C. The effectiveness of aluminium diffusion coatings on the oxidation resistance of pure molybdenum, niobium, tantalum, and tungsten was investigated. Homogeneous diffusion layers of Al-rich intermetallic phases were formed on all four refractory metals after pack cementation. Thermodynamic calculations and experimental assessments (e.g., of the activator) determined the most suitable conditions for the pack cementations. Subsequent thermogravimetric analysis of the uncoated and coated samples at700°C and 900°C for up to 100h in dry synthetic air was used to determine the protective effect of the coatings and investigate the underlying oxidation mechanisms. Optical and electron microscopy, EPMA, XRD and Raman spectroscopy were used to investigate the diffusion layers and the oxide scales. For two refractory metals (Mo and Ta) the aluminization resulted in an improved oxidation behavior and a substantially decreased oxide growth rate compared to uncoated substrates.