K. Beck, A.S. Ulrich, N. Thor, C. Oskay, M.C. Galetz

International Journal of Refractory Metals and Hard Materials 121 (2024), 106626, DOI: 10.1016/j.ijrmhm.2024.106626

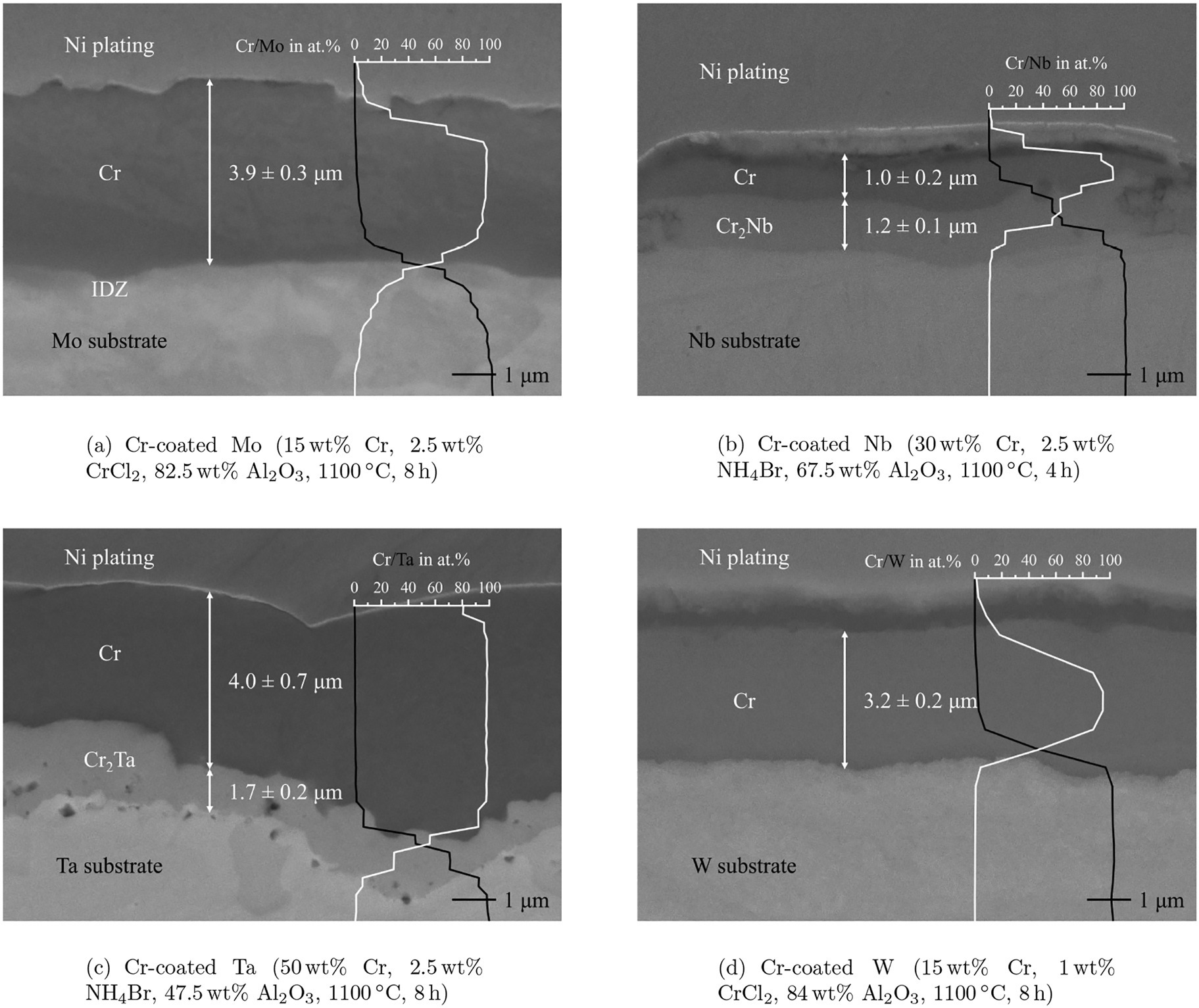

Due to their very high melting points and high mechanical strength at elevated temperatures, refractory metals are promising structural materials for high temperature applications. However, their application is strongly restricted by their insufficient oxidation resistance. In this fundamental study, four different refractory metals (Mo, Nb, Ta, and W) were chromized by pack cementation to investigate the influence of chromium diffusion coatings on their oxidation resistance at intermediate temperatures. Thermodynamic calculations were used to find the most suitable conditions for the pack cementations. The formation of a homogeneous single-phase bcc Cr layer with a thickness below 10 μm on the sample surface was observed on all four refractory metals. In the case of Nb and Ta, intermetallic Cr2X-Laves phases (X = Nb, Ta) formed underneath the bcc Cr layer while an interdiffusion zone formed on Mo. The concentration profiles of the deposited Cr layers were used to determine the diffusion coefficients graphically via Boltzmann-Matano analysis. The Cr-coated samples were analyzed via thermogravimetric analysis at 700 °C and 900 °C for up to 100 h in dry synthetic air. Optical and electron microscopy, EPMA, EBSD and XRD were used to investigate the chromium diffusion layers and the oxide scales.