01IF22689N BG/2

| Period: | 2023-01-01 to 2025-06-30 |

|---|---|

| Partner: | RWTH Aachen – Institut für Eisenhüttenkunde (IEHK) |

| Funder: | AiF |

| Project Manager: | Beyza Öztürk |

|

Department: |

Materials and Corrosion |

| Team: | High Temperature Alloys |

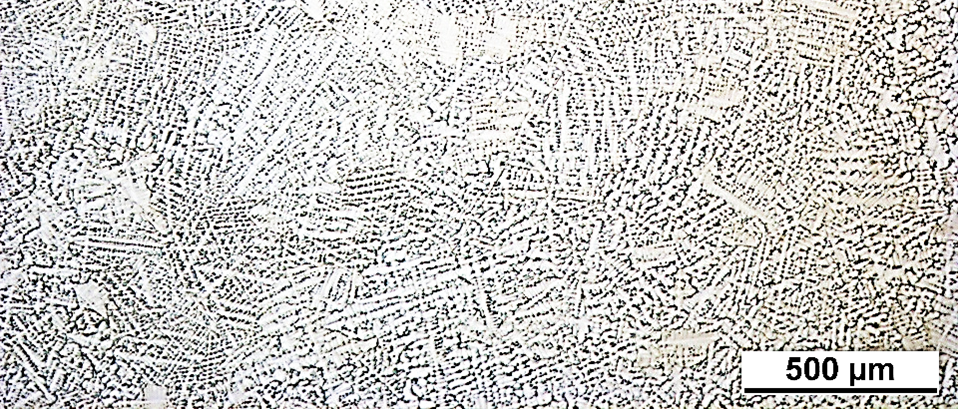

In a previous AiF-funded project ("AM Hochtemperaturbauteile", Grant number 20904 N), it was shown that Ni-Cu alloys with Cu content could exhibit metal dusting attack despite the inhibiting effect of Cu. In this project, Ni-Cu alloy is chosen as the base material, and oxide formers were added to the Ni-Cu alloy to form a barrier and improve its resistance to metal dusting. Aluminum oxide is suitable for this purpose as Al2O3 is slow-growing and thermodynamically stable under Metal Dusting conditions. In this project, the process parameters for powder atomization of Ni-Cu alloys with high aluminum content will be determined. Then, process parameters for low-defect Laser-Powder-Bed-Fusion-Fusion-Process (LPBF) will be established. In the meantime cast and later the additively produced components will be investigated as a function of aluminum content. Finally, an overview will become available of process-structure-property relationships in terms of mechanical properties and corrosion resistance of the alloys.

back

Das IGF-Vorhaben Nr. 01IF22689N BG/2 der Forschungsvereinigung DECHEMA e.V. wird über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

Beyza Öztürk

Tel.: +49 69 / 7564-362

E-mail: beyza.oeztuerk