01IF22658 N

| Period: | 01.10.2022 - 30.09.2025 |

|---|---|

| Partner: | Christof Langer; fem |

| Funder: | IGF (BMWK) |

| Project Manager: | Dr. Sigrid Benfer; Dr. Hendrik Schewe |

| Team: | Electrolytic Corrosion; Microbial Biotechnology |

In today's globalized society, diseases can spread rapidly and easily across borders, with disastrous consequences for the health of the population and the state of the national economy. Due to different routes of infection transmission (aerosol or droplet infection, smear infection by touching contaminated surfaces), no single solution exists to prevent the spread of viral infections. Thus, multiple approaches are needed to effectively reduce the transmission of viruses. For this purpose, antiviral surfaces will be increasingly used in the future, especially in public facilities such as schools, health centers, public transportation or airports. Thus applications require the use of durable materials with long-term (weeks or months) antiviral efficacy. Anodized aluminum materials represent a highly interesting substrate material in this context, as the meso- and macroporosity of the surface is particularly suitable for functionalization with an additional virucidal or bactericidal property. Furthermore, aluminum is already in use today in many potential areas of application or can easily replace materials previously used there for certain components (e.g. handrails, grab handles, door handles, sanitary equipment, etc.).

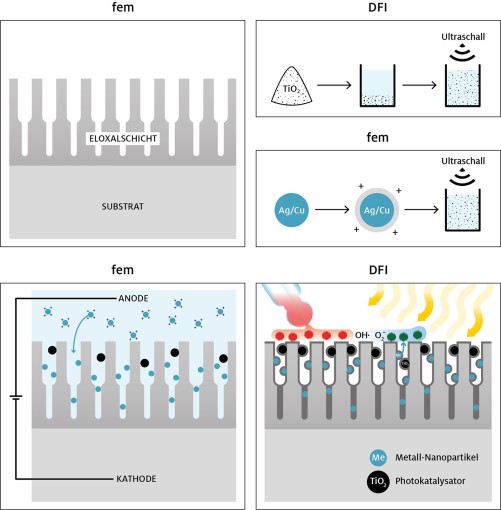

The aim of this research project is to use the inherent pore structure of anodically oxidized aluminum substrates to endow them with antiviral and antibacterial properties. This should be realized by incorporating metallic as well as photocatalytically active nanoparticles into the open pore structure of the anodized material. The technical challenge in developing the layers is to design them in such a way that the intercalation of the particles succeeds without affecting the essential properties of the anodized layer and – in addition – to ensure an antiviral function and a strong bond between the substrate and the nanoparticles. This is to be achieved by electrophoretic deposition of the nanoparticles.

The planned project involves three basic steps, (1) the targeted structuring of a multilayer anodizing system for the subsequent incorporation of nanoparticles, (2) the synthesis of virucidal and bactericidal nanoparticles, and (3) their incorporation into the anodized pores. This also includes proof of the mode of action, particularly with regard to the certification of subsequent products (biocide regulation). Crucial for the success of the project is the production of the smallest possible antiviral nanoparticles (ideal: particle sizes ≤20 nm) as well as the incorporation behavior of the different nanoparticle systems. A synergistic effect in the antiviral effect should be achieved by combining the mechanisms of action (direct + indirect disinfection) by intercalation of metal nanoparticles and photocatalysts (s. Figure).

Figure: Scheme of the different process steps

Conceivable applications include surfaces from the fields of hygiene, sanitary and medical technology or also in the field of mobility, in particular public transport, which will make a significant contribution to CO2 reduction in the context of climate policy. In order to minimize the financial burden on SMEs in implementing the project results, the process can be integrated into existing anodizing lines.

back

Das IGF-Vorhaben wird durch das Bundesministerium für Wirtschaft und Klimaschutz aufgrund eines Beschlusses des Deutschen Bundestages gefördert.