19655 N

| Period: | 2018-01-01 to 2021-04-30 |

|---|---|

| Funder: | Federal Ministry for Economics and Energy (BMWi, Germany) via AiF |

| Project Manager: | Lukas Mengis |

| Team: | High Temperature Materials |

Belonging to the intermetallic phases, gamma-based titanium aluminides have already been established as high-temperature materials in aerospace applications. In the low-pressure section of today’s turbine engine they have substituted heavier nickel-based superalloys as blade materials because of their outstanding combination of thermo-physical properties. Most notably they possess low density (~3.9-4.2 g/cm³), high-temperature strength as well as good oxidation and creep resistance.

Their oxidation resistance at temperatures above 750°C, however, is insufficient and thus rules out their potential application in the hotter stages of the engine, which would otherwise lead to an additional increase in overall process efficiency. Furthermore, as turbine blades are usually fitted into the turbine disc using a unique dovetail construction, metallic surfaces are inevitably in direct contact under high mechanical loads and temperatures inducing friction and wear.

As previous studies focus mostly on improving either the oxidation or the wear resistance of the substrate using a respective coating, a combined approach is undertaken within the scope of this study addressing both drawbacks equally.

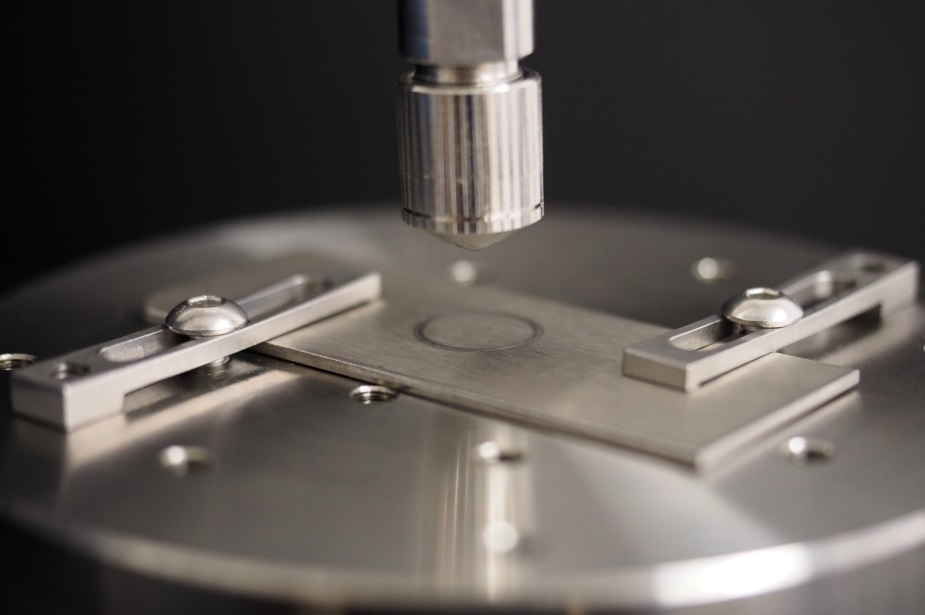

The basic oxidation behaviour of the bare substrate will be investigated at different temperatures and under variation of the exposure time (up to 1000 h). Additionally, the tribological properties of the substrate will be tested from room temperature up to 800°C using a tribometer (pin-on-disk) with various counterpart materials. Finally, coated samples will be tested under long-term high-temperature conditions to investigate their required oxidation resistance, while high-temperature pin-on-disk measurements will be used to characterize the modified wear and friction behaviour.

back

Das IGF-Vorhaben Nr. 19655 N der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.

PD Dr. Mathias Galetz

Telephone +49 69 / 7564-397

E-mail: mathias.galetz

L. Mengis, C. Oskay, N. Laska, M.C. Galetz, Intermetallics 163 (2023), 108039

L. Mengis, C. Grimme, M.C. Galetz, Wear (2021), 203818

L. Mengis, C. Oskay, A. Donchev, M.C. Galetz, Surface and Coatings Technology 406 (2021)

L. Mengis, A.S. Ulrich, P. Watermeyer, C.H. Liebscher, M.C. Galetz, Corrosion Science 178 (2021), 109085

L. Mengis, C. Grimme, M.C. Galetz, Wear 426-427 Part A (2019), 341