| Period: | 01.05.2021 – 31.12.2024 |

|---|---|

| Funder: | |

| Project manager: |

Markus Pyschik |

| Team: | Sustainable Electrochemistry |

Biogas plants are an important pillar for a sustainable energy and raw material supply, especially in times of moving away from fossil fuels and raw materials.

Due to the daily and seasonal differences in the increasing electricity generation from solar and wind energy, it is necessary to balance the fluctuations with the help of flexible power plants and electricity consumers. In order to react quickly and efficiently to these fluctuations, biogas plants as sustainable energy producers must become more flexible. Research in this field is mainly concerned with technologies for power delay or intermediate storage of biogas and heat. Here, biogas and heat can be stored and used with a time delay in the event of negative residual load (power surplus). The storage capacity is usually at least 12 hours to compensate fluctuations within a day. In case of a positive residual load (power scarcity), electricity and heat can be generated from biogas as usual to contribute to the stabilization of the electricity grid.

In addition to the power delay and the energetic use of biogas, biogas can also be used as a raw material. Especially for biogas plants in rural areas without a connection to the gas grid, flexibilization for material use of biogas can offer an alternative to fossil raw materials.

The aim of the eBiFlex project is to make the operation of biogas plants more flexible by the development of a concept for an electrochemical refinery (e-refinery). In phases of a power production above the residual load, (cheap) power from the grid or from local producers of renewable energies can be used to electrochemically convert biogas into bio-methanol, a basic chemical, which is easy to store and transport. This process is also suitable for continuous methanol synthesis as an alternative to the thermal use of biogas.

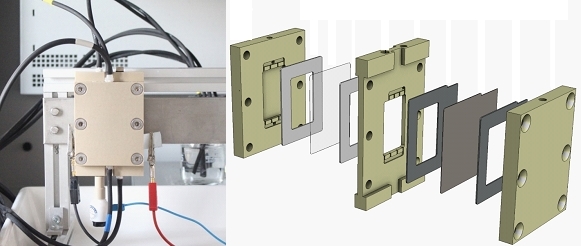

The research work at the DECHEMA Forschungsinstitut is therefore concerned with the development and operation of gas diffusion electrodes (GDE) for oxidative methanol synthesis from the methane fraction of biogas. The focus of the project is on the selection of suitable catalysts to achieve a selective oxidation at high current densities. In addition, a suitable cathodic counter-reaction should be evaluated to increase the cost efficiency of the electrochemical process by producing valuable materials at both electrodes.

The concept thus contributes significantly to innovative agricultural energy management and sustainable material production and offers the possibility of increasing the economic viability of the residual load-dependent operation of biogas plants.

back