19082 BG

| Period: | 01.04.2016 - 31.05.2019 |

|---|---|

| Partner: | Fraunhofer IKTS Dresden |

| Funder: | AiF |

| Project Manager: | Dr. Adrian Anthes |

| Research Group: | Corrosion |

Motivation and Aim

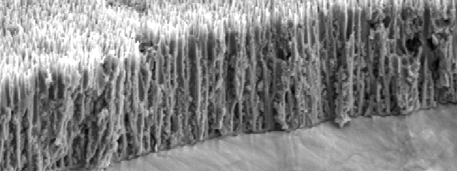

Aluminum and Al alloys are nowadays used not only for automotive and aircraft construction, but also for building claddings, windows, etc., in the construction industry. In order to protect the base metal from corrosion, the surface is anodized, whereby the native / thin oxide layer is artificially thickened. The oxide layer thus produced is several microns thick and has pores of which the diameters lie in the one to three-digit nanometer range (depending on the anodizing method). The present pores are generally sealed in a downstream process step (water vapor) or cold (chemical) in order to increase the corrosion resistance. However, the thus densified alumina (passive layer) is only stable up to a pH value of approx. 8.5, whereby recurring cleaning with strongly basic cleaning chemicals (pH 13.5) leads to a corrosive attack of the surface. However, an adequate long-term stability of anodized aluminum and Al alloys against alkaline media is required by the user, which is to be achieved within the framework of the project by a corresponding surface modification.

Approach

The aim of the ongoing project is to develop an anodizing process based on sulfuric acid anodizing (SAA), which allows subsequent chemical nanotechnology impregnation to increase resistance to strongly alkaline media. The modification of the anodizing parameters (current-voltage regimes, temperature and bath composition) should directly influence the pore morphology, so that the pore diameter and shape are optimized for the subsequent impregnation. The impregnation is to be carried out using aqueous nanoparticulate zirconium dioxide dispersions since zirconium dioxide has a high resistance to strong acids and bases. In addition, the coefficient of expansion of zirconium dioxide is approximately equal to that of aluminum oxide, which means that thermal stress should not be a problem for the generated layers. The impregnated anodizing layers are then to be characterized by modern analytical methods and their corrosion behavior both electrochemically and by aging in typical basic cleaners.

Results

The impregnation with zirconia nanoparticles was first tested on phosphoric acid anodized samples (pore diameter of 50 nm). For this, a commercial zirconia dispersion (primary particle size 3 nm) stabilized by acetic acid with a pH of about 3.5 has been used. In this case, depending on the solids content, a filling of the pores with top layer formation or without top layer formation could be achieved. First electrochemical investigations suggest that the impregnation can increase the barrier resistance of the passive layer. Although the pore diameter could be increased by optimizing the process parameters (additives, current-voltage regimes) during sulfuric acid anodization, an enlargement of the pore diameter in pure sulfuric acid was not possible. First dip coatings/ impregnations of SAA layers (pore diameters of 25 nm) were carried out and examined electrochemically.

Future work

The future work includes the investigation of impregnated SAA layers by means of FE-SEM in order to be able to detect nanoparticles directly in the pores. The impregnated SAA samples should be compared with industrially anodised samples (benchmark), which were also impregnated with the zirconium dioxide dispersion. Subsequently, the samples are to be electrochemically characterized and tested for their corrosion resistance in basic media.

back

Das IGF-Vorhaben Nr. 19082 BG der Forschungsvereinigung DECHEMA e.V., Theodor-Heuss-Allee 25, 60486 Frankfurt am Main wurde über die AiF im Rahmen des Programms zur Förderung der industriellen Gemeinschaftsforschung (IGF) vom Bundesministerium für Wirtschaft und Energie aufgrund eines Beschlusses des Deutschen Bundestages gefördert.