| Period: | 01.09.2014 – 31.08.2017 |

|---|---|

| Partner: |

TU Clausthal, TU Berlin, FZ Jülich & IoLiTec GmbH Hoppecke GmbH, Gaskatel GmbH & Technion Israel Institute of Technology |

| Funder: |

Federal Ministry of Education and Research (BMBF) Funding code: 03SF0486B |

| Project Manager: | Nicky Bogolowski |

| Research Group: | Chemical Technology |

Motivation

According to German government strategy, contribution of renewable energy sources to electricity mix should reach 35% by 2020. In order to satisfy consumer demand, however, many challenges mostly linked to seasonal fluctuations have to be overcome. Because of their higher theoretical energy density, lower toxicity, less expensive electrode materials and non-affinity to thermal runaway like e.g. Li-based systems, metal/air batteries such as Al, Si and Zn/air are attractive candidates for sustainable energy storage applications

Background

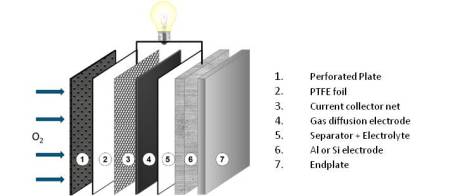

Large scale commercialisation of metal/air batteries is actually hindered by some inherent drawbacks related to the metal electrode such as poor reversibility, formation of passive layer such as Al(OH)3 in Al/air, shape change and dendrite formation in Zn/air as well as low energy efficiency due to high overpotential and carbonate precipitation at the air electrode in alkaline electrolyte. In this context, recent developments in ionic liquids (IL) based aprotic electrolyte such as EMI-Cl/AlCl3 open exciting perspectives especially with respect to suppression of passive layer and carbonate formation. Most of the ILs, however, have a reduced ionic conductivity that limits current density. A typical metal/air battery design is shown in figure 1.

Figure1: Metal/air battery set-up

Objectives

The “AlSiBat” project aims at the development of a primary Si/air and secondary Al/air battery with appropriated IL-based electrolytes. The R&D activities of DFI in that project focus principally on the synthesis and characterization of bifunctional catalysts for oxygen reduction (ORR) during discharging and oxygen evolution (OER) during charging as well as fabrication of IL gas diffusion electrodes (GDE).

Acknowledgements

Federal Ministry of Education and Research (BMBF) is gratefully acknowledged for financial support (Förderkennzeichen: 03SF0486B)

backDr.-Ing. Jean-François Drillet

Tel.: 069 / 75 64-476

E-Mail: drillet

Dipl.Chem. Nicky Bogolowski

Tel.: 069 / 75 64-485

E-Mail: bogolowski

Final report (in German) (pdf)

N. Bogolowski, J.-F. Drillet ECS transactions, Prime 75/22 (2017) 85-92

N. Bogolowski, O. Ngaleu, M. Sakthivel, J.-F. Drillet Carbon 119 (2017) 511-518

N. Bogolowski, J-F. Drillet Electrochimica Acta, 274 (2018), 353–358